Vacuum Coating Machine for jewelry

When it comes to coating jewelry, many coating service providers will use electroplating, dip coating, or thermal spraying because that is what has always been used. Now many manufacturers are moving their services from traditional coating to vacuum coating after recognizing the benefits of it.

The PVD coating system provided by BITE Vacuum Technology represents arguably the world's most advanced coating technology. The vacuum coater uses PLC and touch screen to control the entire deposition process to ensure constant results each time the product is processed. More importantly, PVD coating process is environmentally friendly and energy efficient, producing a uniform deposit with better adhesion than provided by traditional coating processes.

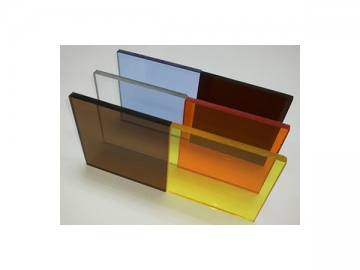

Colors to Be Applied

By combining various metals with different reactive gases, BITE vacuum coater can apply an array of colors and surface finishes to the substrate, including

Titanium

Zirconium

Satin Finish

Black

Color combo

Materials to Be Applied

Another advantage of physical vapor deposition is the wider choice of materials to be deposited, including gold, silver, TiN, TiC, ZrN, TiAl, CrN, and more. The vacuum coating can have gold mixed in it which greatly enhances its wear resistance. That is also why the shiny plating you see on some jewelry does not tarnish or lose its eye-dazzling sheen easily.

Recommended Models