Coating Machine

LHF series powder coating machine is mainly used for the surface modification of powder materials (range from 325 mesh to nanometer sized), like ground limestone, precipitated light calcium carbonate, washed kaolin, calcined coal kaolin, magnesium hydrate, superfine and precipitated barite and zinc oxide, etc.

In some occasions, this kind of powder surface modification machine also functions as a disaggregating machine.

- Continuous operation is possible, thus guarantee a high production capacity.

- Working independently or working in a production line (combined use with superfine grinding mills, etc.) are both possible.

- High coating ratio; high activation index; low consumption of modification agent.

- No material aggregation: as a result, finished products can be packaged directly.

- Low power consumption:

- lowest power consumption could be 30 kwh/t;

- self-generated heat of the machine can be directly used for material's surface engineering; as a result, there is no need of any other additional heating system.

- Modification temperature can be adjusted to meet different requirements.

- Eco-friendly: negative pressure production help offer a dust-free production environment.

Feeding material into powder surface modification machine → adding into modification agent → material and modifier will fully mixed together when the modification machine is operating at high speed; and the heat, which is generated for the high speed movement of machine and material, will also help finish material coating at the same time → finally, the finished products will be collected by the negative pressure collection system.

| Data \ Model | Main power(kw) | Capacity(t/h) | Coating efficiency |

| LHF-500 | 33 | 0.3-1.2 | ≥98% |

| LHF-1000 | 55 | 0.6-3 | ≥98% |

| LHF-2000 | 110 | 1.2-6 | ≥98% |

| LHF-3000 | 165 | 2-9 | ≥98% |

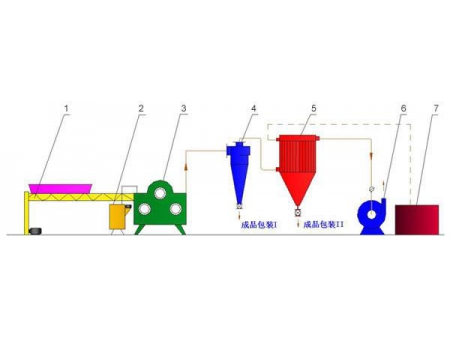

1. Powder feeding system

2. Modifier feeding system

3. Modification machine

4. Cyclonic collector

5. Bag collector

6. Induced draft fan

7. Air compressor

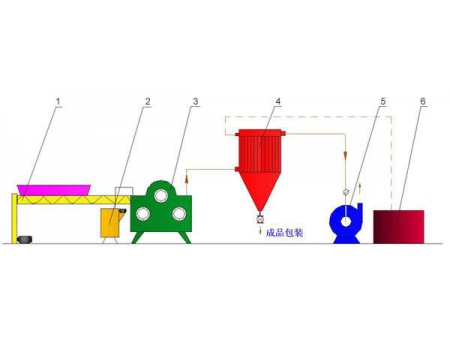

1. Powder feeding system

2. Modifier feeding system

3. Modification machine

4. Bag collector

5. Induced draft fan

6. Air compressor

1. Material feeding mechanism I

2. Powder feeding system

3. Modifier feeding system

4. Modification machine

5. Bag collector

6. Material feeding mechanism II

7. Screening system

8. Induced draft fan

9. Air compressor