Learn About Plastic Injection Molding

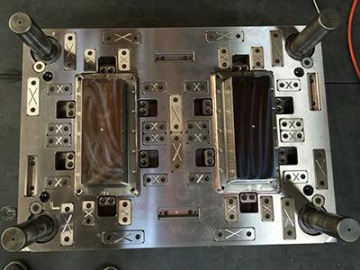

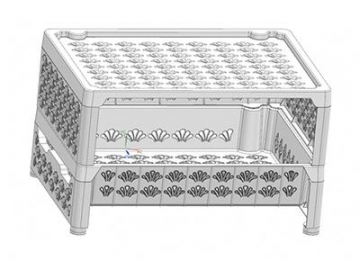

Injection molding is a manufacturing process to produce parts by injecting plastic materials into a mold. An injection mold is an important tool for mass production of a plastic product. During the manufacturing process, the mold is first clipped on the injection machine. Then, melted plastic is injected, cooled and formed in the mold. Finally, the finished product is separated from the mold. The entire process is done in a cyclic fashion, and today, plastic injection molding has a wide application range in the production of automotive parts, food packaging, home appliances, furniture and daily necessities.

As a key part in injection molding, the injection mold plays a vital role in the entire injection process and its quality directly determines the final product quality, manufacturing efficiency and profit. Therefore, to meet the high requirements for injection molding, a set of qualified plastic injection molds must have a reasonable design, convenient maintenance and effective cooling methods. Thus, a short forming cycle, low defect rate and long service life are guaranteed.

Advantages of Our Molds- The injection molds have a reliable quality, thus effectively cutting the time and cost for maintenance and repair, decreasing the downtime and increasing the production.

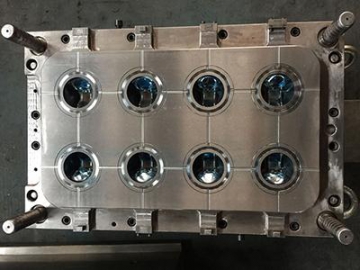

- Implementing an optimal waterway cooling design, the injection molds will shorten the forming cycle, so that more products can be produced in the same period as compared to a conventional mol.

- Our molds are known for high stability and have an ultra-low defect rate. The client's manufacturing costs is greatly reduced and profit is enhanced.

- The manufacturing of our plastic injection molds makes use of standard molds, making sure a single mold can produce many similar products. The client only needs to replace the mold core and mold cavity, saving the mold cost.

With the application of our high-quality, highly efficient and long service life molds, countless plastic products manufacturers receive outstanding economic and social benefits. In turn, these manufacturers recommend our company to their friends, informing more people of what we can do. By knowing the importance of injection mold quality, we achieve a win win relationship with our customers.