Injection Molding for Packaging Industry

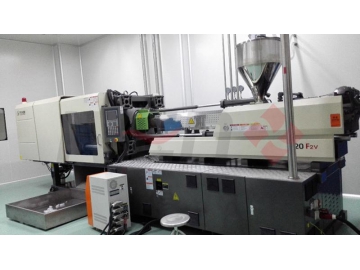

AERO MOLD offers mold customization services for plastic packaging industry uses, including cosmetics packaging molds, food packaging molds, beverage bottle injection molds, disposable container molds and other plastic packaging molds.

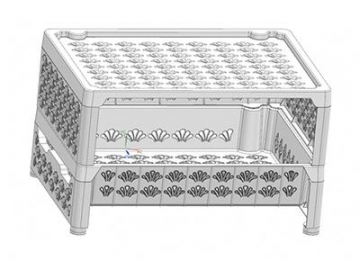

Design drawings Plastic Cups for Airline Use

Plastic Cups for Airline Use Plastic Cups for Airline Use

Plastic Cups for Airline Use Disposable Food Container

Disposable Food Container Plastic Food Container with Lid

Plastic Food Container with Lid Plastic Spray Bottle Cap

Plastic Spray Bottle Cap Plastic Bottle Cap

Plastic Bottle Cap Plastic Bottle Closure

Plastic Bottle Closure

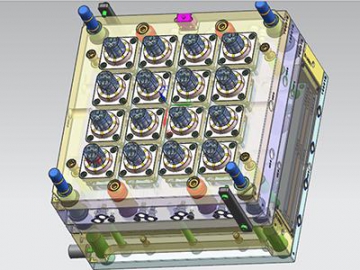

AERO MOLD has successfully developed a variety of food packaging and cosmetic packaging molds, and will turn your concept into reality. Simply provide us with your sample product that requires a mold, and we will design a 3D mold. We also design the 3D mold based on complete design drawings and parameters, all to ensure a complete mold customization service.

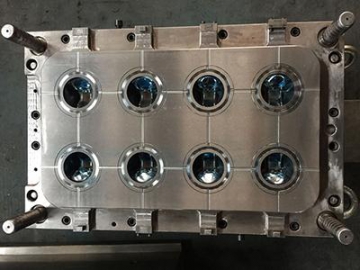

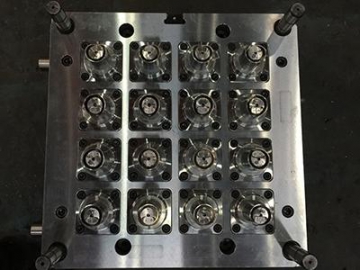

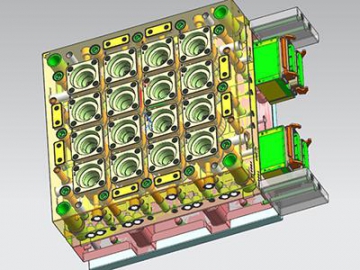

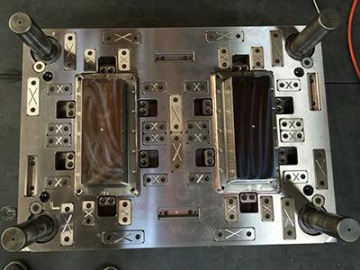

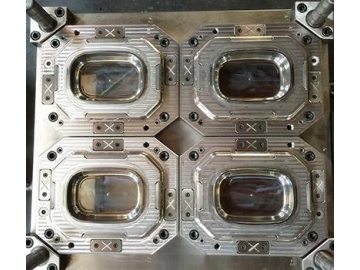

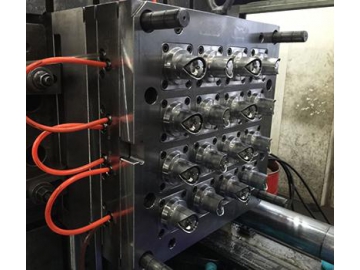

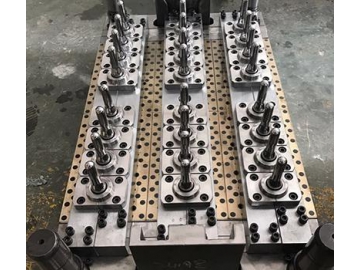

We operate a variety of highly precise CNC machines, which are used to process molds with a complex structure. We also offer highly efficient manufacturing for molds with multiple cavities, including 2-cavity molds, 4-cavity molds, 12-cavity molds, and 64 cavity molds, all according to customer requirements.

We also offer various thin walled injection molds with a minimum thickness of 0.4mm.

Materials used to produce thin walled injection molds:- Mold base: Plastic mold steels of P20 and 2316 are used for the production of thin wall packaging molds, which avoids mold corrosion and water leaking through any loose connections.

- Mold core, mold cavity: Heat treated 2344 steel, S136 steel and other steels will undergo heat treatment to obtain a hardness of HRC 48-52. This design ensures a long mold life, and helps decrease the risk of mold rusting.

- Insert: Some inserts, such as the heated nozzle, are made using a heat treated S136 or 2083 steel. Not only that, but an insert installed on the top of the male mold's core uses BeCu (Beryllium Copper) instead of other materials, as BeCu is able to withstand the higher temperatures and poor heat dissipation found when inserts are located extremely close to the heated nozzle.

PS Airline Cup Injection Molds

PS Airline Cup Injection Molds Hot Runner Molding for PP Disposable Food Container

Hot Runner Molding for PP Disposable Food Container Two shot PP Cosmetic Molds, Flip-Top Molds

Two shot PP Cosmetic Molds, Flip-Top Molds PP Air Freshener Sprayer Molds, Husky Hot Runner

PP Air Freshener Sprayer Molds, Husky Hot Runner PET Perform Mould

PET Perform Mould