Furniture Making (hot melt adhesive for wood binding and edge binding)

Hot melt adhesive with high viscosity and fast curing speed can greatly simplify the work of repairing and producing furniture. These materials can be used for processes such as edging binding and gap filling.

We recommend the following hot melt adhesives with different appearances and properties for the furniture industry. These adhesives feature excellent resistance to water and temperature, creating bonds that are more durable and secure.

Typical applications- Sealing the edge of artificial board

- Gluing together thin layers of plywood

- Joining wood boards

- Creating a mortise and tenon joint

1. Hot melt adhesive pellets

The following two types of hot melt adhesive pellets with excellent heat resistance and high curing speed, are commonly applied to seal the edges of artificial board and connect wood board with others, as well as glue the thin layers of plywood.

| Model | 8150M polyamide hot melt adhesive pellets | 8120M polyamide hot melt adhesive pellets |

| Appearance | Buff, transparent, pellet | Buff, transparent, pellet |

| Viscosity | 2800cps~4000cps/200℃ | 1800cps~3500cps/200℃ |

| Softening point | 145℃~155℃ | 115℃~125℃ |

| Operation temperature | 180℃~200℃ | 160℃~180℃ |

| Glass transition temperature | 0℃ | 0℃ |

| Curing speed | 3s~5s | 3s~5s |

| Density | 0.95g/cm3 | 0.95g/cm3 |

| Acid value | <6mg(KOH)/g | <7mg(KOH)/g |

| Amine value | <3mg(HCL)/g | <3mg(HCL)/g |

| Weight/package | 25kg/sack paper bag | 25kg/sack paper bag |

| Storage | Cool and dry | Cool and dry |

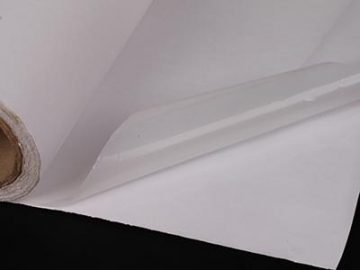

2. Hot melt adhesive stick

The hot melt adhesive stick is commonly used to glue together thin layers of plywood and is directly used in hot melt glue equipment. Users can melt the glue stick and then apply it to a wood veneer along the wood grain and then glue the veneer together with adjacent veneers. This makes plywood durable and prevents delamination.

| Model | 8120N | 8150N | 5005N |

| Material | PA | PA | EVA |

| Appearance | Yellow, transparent,stick | Yellow,transparent,stick | Ivory-white, non-transparent, stick |

| Viscosity | 1800cps~3500cps/200℃ | 2800cps~4000cps/200℃ | |

| Softening point | 115℃~125℃ | 145℃~155℃ | 115℃~125℃ |

| Operation temperature | 160℃~190℃ | 190℃~210℃ | 160℃~180℃ |

| Glass transition temperature | 0℃ | 0℃ | -10℃ |

| Curing speed | 3s~5s | 5s~8s | 15s~30s |

| Density | 0.95g/cm3 | 0.95g/cm3 | 1.1g/cm3 |

| Acid value | <7mg/g | <7mg/g | |

| Amine value | <3mg/g | <3mg/g | |

| Weight/package | 25kg/carton | 25kg/carton | 25kg/carton |