High Temperature Alloy Cutting Tools

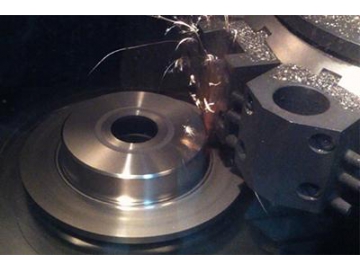

High temperature alloy is a metal material used in high temperature environments (often above 600 ℃) for long periods of time. It is known for its excellent high temperature resistance, good oxidation resistance and thermal corrosion resistance, so it is also known as a "Super alloy". This material is mainly used in the aerospace field to produce high precision parts. When cutting this materials, the PCBN insert must have a high PCBN content with a low grain size. PCBN inserts we've produced for this purpose generally have an 88-90% PCBN content, and meet all requirements for high temperature alloy cutting as it will quickly cut materials without sacrificing accuracy or quality.

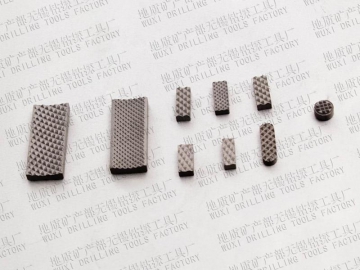

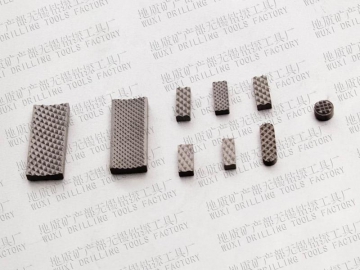

REALY has produced the following PCBN inserts to cut high temperature alloys:(55° Diamond PCBN Inserts BNS-610 Series Cutting Tool)

| TYPE | CORNER RADIUS | PCBN Content | PCBN Grain Size | Cutting Edge Length | Recommended Application | |||||||

| 02 | 04 | 06 | 08 | 10 | 12 | 16 | 20 | |||||

| DNM(G)N0903 | √ | √ | √ | √ | 88%-90% | 1μm-3μm | custom made | cast high temperature alloy | ||||

| DNM(G)N0904 | √ | √ | √ | √ | ||||||||

| DNM(G)N1104 | √ | √ | √ | √ | √ | √ | ||||||

| DNM(G)N1504 | √ | √ | √ | √ | √ | |||||||

| DNM(G)N1506 | √ | √ | √ | √ | √ | √ | √ | |||||

(35° Diamond PCBN Inserts BNS-610 Series Cutting Tool)

| TYPE | CORNER RADIUS | PCBN Content | PCBN Grain Size | Cutting Edge Length | Recommended Application | |||||||

| 02 | 04 | 06 | 08 | 10 | 12 | 16 | 20 | |||||

| VNM(G)N0903 | √ | √ | √ | √ | 88%-90% | 1μm-3μm | custom made | cast high temperature alloy | ||||

| VNM(G)N0904 | √ | √ | √ | √ | ||||||||

| VNM(G)N1204 | √ | √ | √ | √ | √ | √ | ||||||

| VNM(G)N1207 | √ | √ | √ | √ | √ | |||||||

| VNM(G)N1504 | √ | √ | √ | √ | √ | √ | √ | |||||

(Square PCBN Inserts BNS-610 Series Cutting Tool)

| TYPE | CORNER RADIUS | PCBN Content | PCBN Grain Size | Cutting Edge Length | Recommended Application | |||||||

| 02 | 04 | 06 | 08 | 10 | 12 | 16 | 20 | |||||

| SNM(G)N0903 | √ | √ | √ | √ | 88%-90% | 1μm-3μm | custom made | cast high temperature alloy | ||||

| SNM(G)N0904 | √ | √ | √ | √ | ||||||||

| SNM(G)N1204 | √ | √ | √ | √ | √ | |||||||

| SNM(G)N1207 | √ | √ | √ | √ | √ | |||||||

| SNM(G)N1504 | √ | √ | √ | √ | √ | |||||||

| SNM(G)N1507 | √ | √ | √ | √ | √ | |||||||

| SNM(G)N1907 | √ | √ | √ | √ | √ | √ | √ | |||||

| SNM(G)N2010 | √ | √ | √ | √ | √ | √ | √ | |||||

(80° Diamond PCBN Inserts BNS-610 Series Cutting Tool)

| TYPE | CORNER RADIUS | PCBN Content | PCBN Grain Size | Cutting Edge Length | Recommended Application | |||||||

| 02 | 04 | 06 | 08 | 10 | 12 | 16 | 20 | |||||

| CNM(G)N0903 | √ | √ | √ | √ | 88%-90% | 1μm-3μm | custom made | cast high temperature alloy | ||||

| CNM(G)N0904 | √ | √ | √ | √ | ||||||||

| CNM(G)N1204 | √ | √ | √ | √ | √ | √ | ||||||

| CNM(G)N1207 | √ | √ | √ | √ | √ | |||||||

| CNM(G)N1604 | √ | √ | √ | √ | √ | √ | ||||||

| CNM(G)N1607 | √ | √ | √ | √ | √ | √ | √ | |||||

(80° Triangular PCBN Inserts BNS-610 Series Cutting Tool)

| TYPE | CORNER RADIUS | PCBN Content | PCBN Grain Size | Cutting Edge Length | Recommended Application | |||||||

| 02 | 04 | 06 | 08 | 10 | 12 | 16 | 20 | |||||

| WNM(G)N0603 | √ | √ | √ | √ | 88%-90% | 1μm-3μm | custom made | cast high temperature alloy | ||||

| WNM(G)N0604 | √ | √ | √ | √ | ||||||||

| WNM(G)N0803 | √ | √ | √ | √ | √ | |||||||

| WNM(G)N0804 | √ | √ | √ | √ | √ | |||||||

(Round PCBN Inserts BNS-610 Series Cutting Tool)

| TYPE | CORNER RADIUS | PCBN Content | PCBN Grain Size | Cutting Edge Length | Recommended Application | |||||||

| T01 | T02 | T03 | T04 | T05 | T06 | T08 | T10 | |||||

| RNM(G)N0903 | √ | √ | √ | √ | 88%-90% | 1μm-3μm | custom made | cast high temperature alloy | ||||

| RNM(G)N0904 | √ | √ | √ | √ | ||||||||

| RNM(G)N1204 | √ | √ | √ | √ | √ | |||||||

| RNM(G)N1207 | √ | √ | √ | √ | √ | |||||||

| RNM(G)N1504 | √ | √ | √ | √ | √ | |||||||

| RNM(G)N1507 | √ | √ | √ | √ | √ | √ | ||||||

| RNM(G)N1904 | √ | √ | √ | √ | √ | √ | ||||||

| RNM(G)N1907 | √ | √ | √ | √ | √ | √ | ||||||

| RNM(G)N2008 | √ | √ | √ | √ | √ | √ | √ | |||||

| RNM(G)N2010 | √ | √ | √ | √ | √ | √ | √ | |||||

(V Shaped PCBN Inserts BNS-610 Series Cutting Tool)

| TYPE | CORNER RADIUS | PCBN Content | PCBN Grain Size | Cutting Edge Length | Recommended Application | |||||||

| T01 | T02 | T03 | T04 | T05 | T06 | T08 | T10 | |||||

| RCM(G)N0607-V | √ | √ | √ | √ | √ | 88%-90% | 1μm-3μm | custom made | cast high temperature alloy | |||

| RCM(G)N0907-V | √ | √ | √ | √ | √ | √ | ||||||

| RCM(G)N1207-V | √ | √ | √ | √ | √ | √ | ||||||

| RCM(G)N1507-V | √ | √ | √ | √ | √ | |||||||

| RCM(G)N1910-V | √ | √ | √ | √ | √ | |||||||

| RCM(G)N2012-V | √ | √ | √ | √ | √ | |||||||

(Conical PCBN Inserts BNS-610 Series Cutting Tool)

| TYPE | CORNER RADIUS | PCBN Content | PCBN Grain Size | Cutting Edge Length | Recommended Application | |||||||

| T01 | T02 | T03 | T04 | T05 | T06 | T08 | T10 | |||||

| RCM(G)N0607-Z | √ | √ | √ | √ | √ | 88%-90% | 1μm-3μm | custom made | cast high temperature alloy | |||

| RCM(G)N0907-Z | √ | √ | √ | √ | √ | √ | ||||||

| RCM(G)N1207-Z | √ | √ | √ | √ | √ | √ | ||||||

| RCM(G)N1507-Z | √ | √ | √ | √ | √ | |||||||

| RCM(G)N1910-Z | √ | √ | √ | √ | √ | |||||||

| RCM(G)N2012-Z | √ | √ | √ | √ | √ | |||||||

Please contact us with any special requirements you have for cutting high temperature alloys. Backed by years of experience, we will offer the right PCBN insert for your needs.