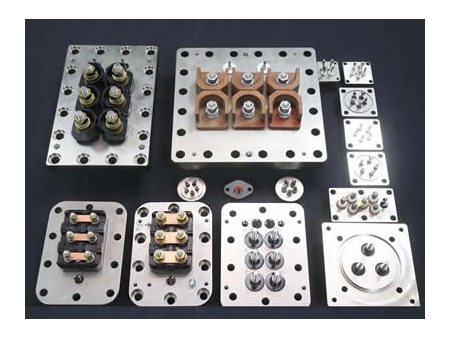

We are metal fabrication experts producing metal parts to your exact specifications. Our skilled technicians will work closely with you to ensure that each component lives up to your standards.

Sheet metal fabrication is the main processing method used in the manufacturing of equipment enclosures and cabinets as well as many other precise metal parts. Our engineers will analyze the drawings of your desired parts and decide on the approach for specific procedures, like cutting, bending, stamping, welding, polishing, painting, and assembly.

Jiatong can handle different sheet metals with thickness range from 0.1 to 6mm and materials including galvanized sheet, stainless steel, aluminum, cold rolled (SPCC) sheet, brass/bronze/copper sheet and etc.

We provide custom sheet metal fabrication service for customers all over the world. Simply upload your product design and select from our range of sheet metal materials, or tell us if you have any specific requirements, and we will get started with your sheet metal fabrication ASAP.

We are capable of small or mass production operations of all sizes of sheet metal parts, and products we have manufactured include chassis, enclosures, panels, brackets, cabinets and other similar sheet metal parts.

-

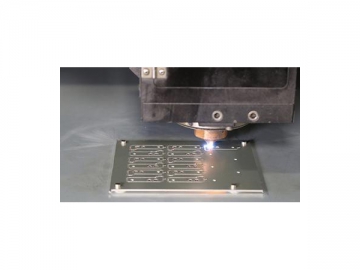

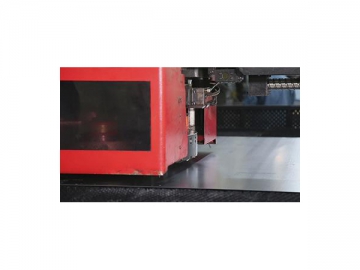

Our designers will turn your 2D/3D designs into real products by laser cutting and engraving your designs on our sheet metal materials, delivering 0.01mm cutting precision.

-

Jiatong is equipped with an NCT turret punch press from AMADA to perform stamping and hole-punching on sheet metal parts. We employ the following advantages to optimize products for customers:

- Our rich experience and highly efficient machines enable shorter processing cycles with significant cost savings and quality assurance.

- The turret punch press operates 5 stampings per second; the punched holes reach a maximum accuracy of ±0.03mm and location accuracy of ±0.1mm.

-

Jiatong combines large-scale and small-scale bending machines. These bending machines are provided by TOYOKOKI and Amada. The key to processing high quality products is the processing equipment. The length of the products we can bend is up to 3m and thickness of the product can be within 0.1-6mm. Therefore, it is possible for us to process all of the products you need.

-

We utilize robotic arms to perform high-precision welds using various methods. For example, we use TIG welding, MIG welding, and resistance welding. We have significant experience in choosing the optimal equipment according to different metals and connection methods.

- Machining

- Powder coating

- Plating

- Anodizing

- Pad printing

- Silk screening

- Fastener insertion

- Rounding of edges

- Tumbling and finishing

- Countersinking

- Riveting ...