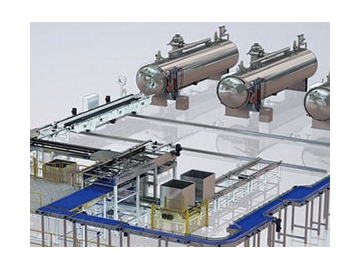

Automated Batch Retort System (ABRS)

Automated Batch Retort System (ABRS)

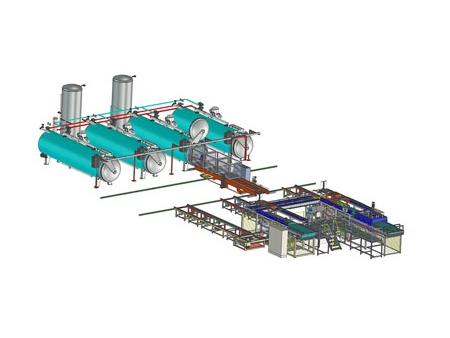

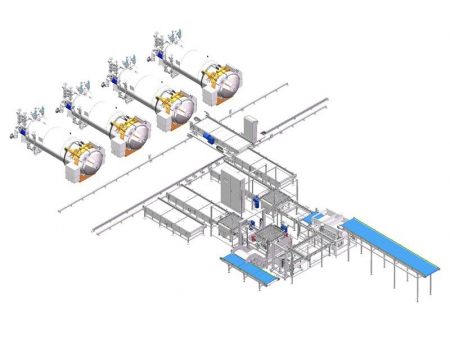

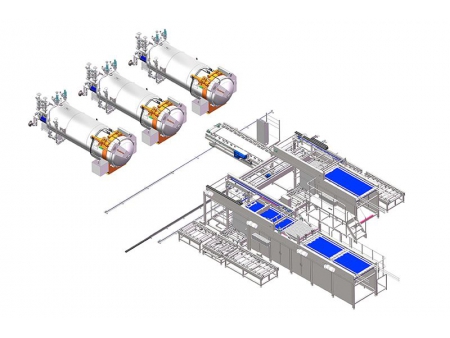

The development trend of food processing is from small vessels to large sterilization retorts so as to improve efficiency and product safety and reduce energy consumption. Larger retort requires larger baskets which cannot be handled manually. The higher labor cost also promoted the gradual change from manual operation to automatic processing. Then, automated batch retort system (ABRS) emerged at the right moment, which is defined as fully automated and completely integrated batch sterilization system. ABRS includes one or several retorts, loading and unloading equipment, basket delivery system and control system.

The packaged products are transported to the loading/unloading system, and then automatically stacked in the basket orderly before being delivered to the retorts. The sterilized products are delivered by the basket conveyor to the unloader. Once the products are unloaded, the conveyor line automatically transfers the finished products to downstream equipment for inspection and packaging.

- Saving 40% of floor space

- High automation level, it requires only one person to operate the entire system

- Large handling capacity and consistent sterilization effect

- Core parts are all purchased from world’s renowned brands to ensure that the entire system operates stably.

- Retort loader/unloader

Our retort basket loader/unloader system is suitable for handling rigid containers (metal cans, glass jars/bottles). Besides, our tray loading/unloading system and tray stacking/destacking system are also available for handling flexible or semi-rigid containers, such as plastic bottles/buckets/cups/trays, pouches, and other fragile containers. - Basket conveyor

DTS offers several options of conveying system for transferring retort baskets or tray stacks to/from the retorts. We also provide customized service according to customer products and site conditions. Please contact our expert team for detailed information! - Software

DTS retort features an intuitive control system, which is jointly developed by our control experts and thermal processing specialists. This feature-rich software meets or exceeds the requirements of 21 CFR Part 11.

The DTS basket tracking system keeps track of each basket to prevent unsterilized containers from being unloaded and transferred to downstream procedures. This tracking system permits operators to monitor all the baskets through the screen, only few operators are required to operate and supervise multiple sterilization systems.

With the basket tracking system, you are able to:

- strictly distinguish between sterilized and unsterilized products

- specify the individuality of each basket

- monitor all the baskets in real time

- track the dwell time deviation of each basket

- ensure that unsterilized containers are not unloaded

- track the container number and production code

- track the state of the basket (unprocessed basket, empty basket, etc.)

- track the retort number and batch number