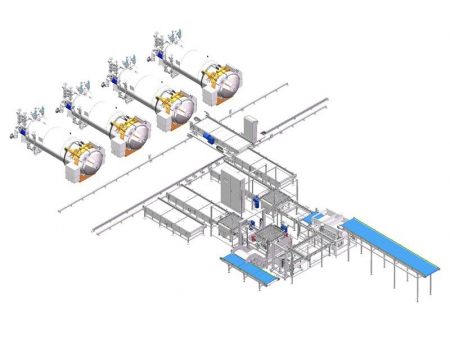

Automatic Retort Loading & Unloading System

Batch retort loading and unloading for flexible packaging

Our flexible packaging retort loading and unloading system is particularly designed to automatically accomplish loading, stacking and unloading of pouches, cans, jars and containers in baskets or trays, as well as tray destacking and package removing after sterilization process.

The automatic retort handling system can be integrated with conveyors that transfer packaged products from upstream packaging equipment to the sterilization retort, and send sterilized products to downstream cleaning equipment, thus achieving unmanned production process of retort room.

Regular Pouch Automatic Loader Unloader by Spider Hands

- High automation, reduce the labor intensity;

- Computer controlled sterilization plate automatic transmission, automatic in and out of sterilization kettle;

- Production quality and efficiency can be controlled, and quality standardization can be achieved;

- Equipment 24 hours uninterrupted operation for the enterprise to create greater profits.

Automatic Irregular Pouch Loader

- Suitable for automatic loading unloading process of large soft bag packaging

- High level of productivity and automation, less labor intensity.

- The loading and unloading process has high efficiency, strong stability and low failure rate;

- Reduce employment costs and management cost;

Mechanical Hands Automatic Pouch Tray Loader Unloader

- Reduce the labor cost;

- Strict quality standardization is performed throughout the production process, ensuring the production quality and efficiency is controlled very well. This avoids worker's emotion impact on the quality and efficiency.

- Automated production greatly reduces labor intensity, and management costs.

- The pouch/tray loader unloader can work continuously for 24 hours/day without any break, which creates more profits for enterprises.

- The high degree of automation improves the market competitiveness among food enterprises.

Swing Head Loader and Unloader

- The retort loader unloader is widely used before and after sterilization of flexible packaged snack food. It can automatically accomplished loading and unloading of the flexible packaged food in the production lines.

- The operations throughout the process are automatically performed by the computer controlled manipulator without human intervention, including tray loading/unloading, tray stacking/destacking.

- The automatic retort loading unloading system helps automate enterprises’ factory processes, significantly reducing labor costs and intensity. Standardized production ensures high quality and efficiency, improving enterprise market competiveness.

This automatic retort loading and unloading system is extensively used in sterilization process for meats, eggs, seafood, corns, vegetables, soy foods, dairy foods and other food products packaged in cans, pouches, jars and containers.

This retort handling system performs automatic loading via weighing, tray loading, telescopic stacking and vacuum absorbing, and automatic unloading via overturning and vacuum absorbing to adapt to different packaging formats and specific requirements. The automated retort loading and unloading system utilizes robotic arm to stack and destack trays. An electric trolley moves between retorts to realize complete automation of loading and unloading operations, and the intelligent system controls the entire loading and unloading system to conduct unmanned operation.

- Ideally alternative to manual tedious tasks of tray loading, stacking and destacking prior to and after food sterilization, greatly saving labor intensity;

- Fully automated loading and unloading operations are implemented by computer control, without requiring human operator intervention;

- Production quality and efficiency will not be affected by operator's emotion, ensuring the safety and quality standardization;

- Less labor cost, reduced production management cost;

- 24-hour continuous operation, yielding a higher profit for manufacturers;