Aluminum Production

DLS Aluminum produces various aluminum plates, coils, foils and aluminum alloy composites. Through many years of development, our aluminum alloy products now cover all alloys from 1000 to 7000 series. Here you will see our production workshops:

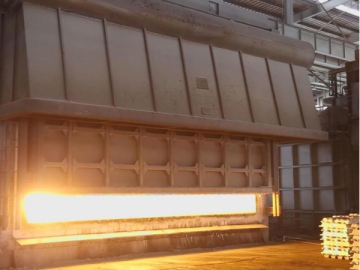

The DLS Aluminum smelting workshop is equipped with a casting line and large horizontal milling line, which can meet the production requirements of the highest aviation grade aluminum alloys.

With the rectangular smelting furnace, we can smelt 1000 to 7000 aluminum alloys with an annual output of over 100 thousand tons.

Two 100-ton soaking pits can realize a daily output of 200 tons.

The large horizontal milling machine has the advantage of three turning milling faces and can provide 450 tons of hot rolled ingots for later processes every day, which can provide strong guarantee for the production demands of customers.

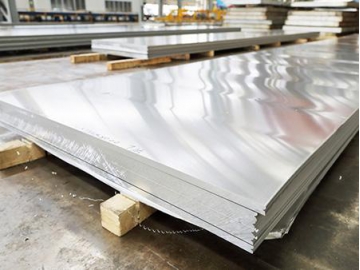

The DLS Aluminum hot rolling workshop is equipped with Italian MINO ‘3300mm rough rolling+2800mm finish rolling’ hot continuous rolling mill, which adopts automatic control system for production operations. This production has the advantages of large width, cross rolling, skew rolling and strong control for plate shape and thickness. Based on this, we can produce various aluminum plates within 3100mm and aluminum coils within 2600mm, which can satisfy requirements for high quality aluminum materials. We can produce many aluminum alloy blanks and hot rolled coils with over 300 thousand tons every year.

DLS Aluminum cold rolling workshop is equipped with MINO 2800mm cold rolling and ACHENBACH 1700mm cold rolling devices and can produce aluminum coils with a maximum width of 2700mm. Aluminum alloys have the advantages of high alloying, high strength, high toughness, large size and high precision.

DLS Aluminum cold rolling workshop is equipped with MINO 2800mm cold rolling and ACHENBACH 1700mm cold rolling devices and can produce aluminum coils with a maximum width of 2700mm. Aluminum alloys have the advantages of high alloying, high strength, high toughness, large size and high precision.

After annealing, finishing processes such as cleaning, straightening, cross cutting and vertical cutting are carried out according to customer specifications, and then aluminum coils, plates, strips and foils products are obtained.