Toffee Candy Production Line

Toffee Candy Production Line

The toffee candy production line adopts international famous brand of PLC which has more stable performance. The pouring speed, holding temperature as well as vacuum cooking temperature and time can be automatically controlled by programming. The frequency control regulates the flow of the sugar liquor accurately, so the obtained massecuite has stable quality. The quantitative filling and mixing of essences, pigments and acid liquor can be finished on line by the dynamic mixer and accurate demoulding can be ensured by the conveying chain belt, cooling system and the dual demoulding mechanism. The process flow and working condition of each part are shown on the

Different shapes of candies can be made by the adoption of different moulds. Chocolate candies can be produced by adding a chocolate quantitative filling system. By replacing part devices and moulds, this production line can also make spherical or flat stereo lollipops.

Specifications

Model | QH150 | QH300 | QH450 | QH600 |

Standard Production Capacity | ||||

Max. Weight of the Candy | ||||

Pouring Speed | 55-65 time/min | 55-65 time/min | 55-65 time/min | 55-65 time/min |

Steam | ||||

Compressed Air | ||||

Requirements of the Working Environment | Temperature 20 | Temperature 20 | Temperature 20 | Temperature 20 |

Total Power | 32KW/380V | 39KW/380V | 48KW/380V | 75KW/380V |

Length of the Entire Line | ||||

Total Weight |

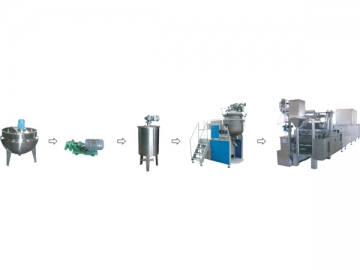

Capable of producing toffees, toffees with fillings, etc., the toffee candy production line is made up of sugar dissolving pot, storage bucket, cooking pot, pouring unit, cooling tunnel and other devices. We provide products with four different standard production capacities, which are

Images of the products produced by our equipment are as follows.