Hard Candy Production Line

Hard Candy Production Line

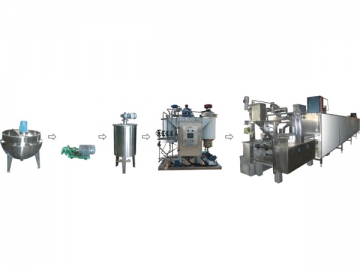

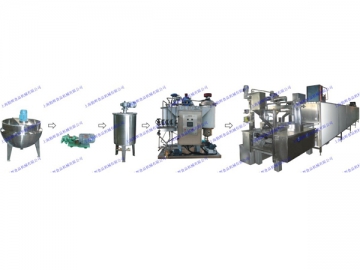

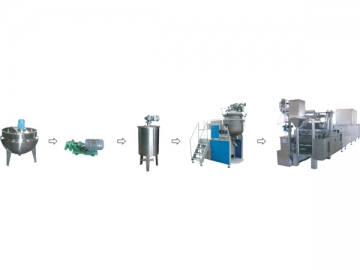

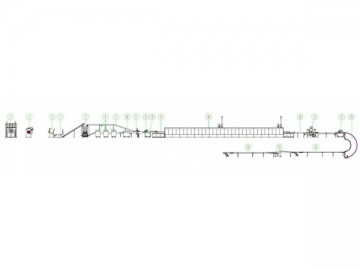

The fourth generation QH series automatic PLC control vacuum film continuous cooking hard candy production line developed based on twenty years of experience is currently the most advanced hard candy pouring equipment at home. It has a compact structure and a high degree of automation. With a high working efficiency, this equipment can produce crystal sugar, bonbons, striped sugar, xylitol, sugarless lollipops, etc., with single color, two colors two flavors, two colors two flavors two layers, or three colors three flavors.

Specifications

Model | QH150 | QH300 | QH450 | QH600 |

Standard Production Capacity | ||||

Max. Weight of the Candy | ||||

Pouring Speed | 55-65n/min | 55-65n/min | 55-65n/min | 55-65n/min |

Steam | ||||

Compressed Air | ||||

Requirements of the Working Environment | Temperature 20 | Temperature 20 | Temperature 20 | Temperature 20 |

Total Power | 27kw/380V | 28kw/380V | 41kw/380V | 64kw/380V |

Length of the Entire Line | ||||

Total Weight |

Candies produced by this production line have smooth surface, clear strips, good taste, accurate amount and position of filling, and other advantages, so they are highly recognized by customers at home and abroad. This entire line is produced according to the GMP standard, enabling food companies to pass easily the certifications of GMP, HACCP, QS, etc.

The international famous brand PLC, which has more stable performance, is adopted. It can be programmed to control the pouring speed, holding temperature, as well as cooking temperature and time. The 10.7-inch touch screen displays process flow diagram and various parameters, facilitating operating and mastering. Flow of the sugar is accurately controlled by the variable frequency speed regulation, yield massecuite with stable quality. Quantitative filling and mixing of essences, pigments and acid liquor is completed by the dynamic mixer and the demoulding is ensured by the conveyor chain belt, cooling system, and dual stripping mechanism.

The hourly production capacity of our product is 150 to

Candies made by this equipment are shown below.