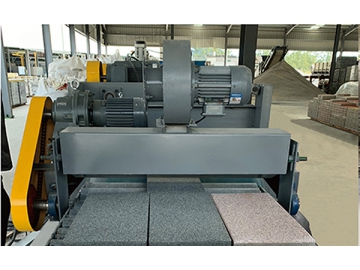

High Effective Grinding Machine

Grinder Construction

The high effectivegrinding machine consists of a grinder, EXC material collector, and ESC dustcollector. It solves the dust flying problem during grinding. The grinder,material collector and dust collector are all made of stainless steel, for easycleaning and reliable operation with low noise. It also conforms to GMPrequirements.

Working Principle of Highly EffectiveGrinding Machine

After raw materials are fed into the grinding chamber, the grinding machine cangrind the materials by taking advantage of the impact force between the movabletooth disk and fixed tooth disc, and the shearing force and friction forcebetween material particles.

Technical Parameter of the Grinding Machine

| Model | 20B-X | 30B-x | 40B-X |

| Capacity (kg/h) | 60-150 | 100-300 | 160-800 |

| Rotate speed of shaft (r/min) | 4500 | 3800 | 3400 |

| Size of feed material (mm) | 6 | 10 | 12 |

| Grinded size (mesh) | 60-120 | 60-120 | 60-120 |

| Grind motor power (kW) | 4 | 5.5 | 11 |

| Dust catch motor power (kW) | 0.55 | 0.55 | 0.55 |

| Overall dimension L*W*H (mm) | 1000*550*1450 | 1350*700*1700 | 1400*720*1750 |

As a professional high effective grinding machine manufacturer and supplier in