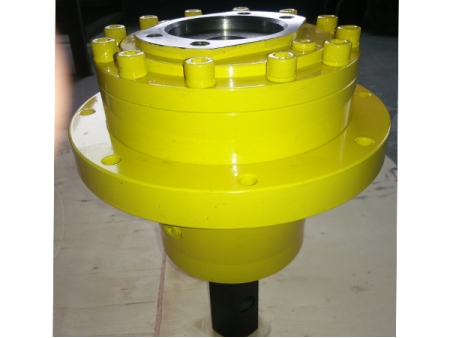

Power Wheel Planetary Gear Drive (American Standard Size)

(Model 3 to model 9, the size of this planetary gear drive is American standard size, which is mainly used in the North American market)

Superior Performance

NBPG planetary drives allow greater flexibility than conventional power train systems and often eliminate the need for components such as drive shafts, axles and chain drives. The many models and styles offered meet a wide range of mobile and industrial application requirements. Single, double and triple reduction ratios can be furnished. In addition, they can be supplied with a variety of motor mounts and inputs which allow them to be used with most makes of hydraulic motors.

Our gearboxes are provided with integral multi disc parking brake and have been designed for direct mounting of hydraulic plug-in motors. The careful choice of the materials and design allows our NBPG planetary drives providing 96 to 98% power transfer efficiency, NBPG planetary drives are significantly more efficient than many other types of drives, including differential design planetaries. The rugged, compact design of these drives saves space and provides for a long service life. All models can be furnished with parking brakes. NBPG has designed integral B4 series parking brakes in Models 4, 6 and 8. These units provide a very compact planetary drive/parking brake package which are particularly useful in applications where space is limited.

NBPG planetary drives deliver the required power for smooth operation and precise control. These units are also fully reversible. Reverse power is easily obtained by reversing rotation of the input. For vehicle applications, the positive traction provided by individually powered wheels results in superior maneuverability and improved ground clearance than conventional drive systems. NBPG planetary drives can be an efficient solution for any application where you need to increase torque or reduce speed to achieve usable power. Let NBPG planetary drives help you put power in its place.

Key Features

1. Output Torque Range: 1000 ... 14000 N.m

2. Gear Ratios: i=2.5 ... 500

3. Gear Unit Versions: In line

4. Output Configuration: Wheel drive, shaft output drive, spindle output drive, swing drive

5. Input Configuration: Adapter for hydraulic motor SAE J 744C, shaft input

6. Hydraulic Brake Input: Hydraulically released parking brake on request.

7. The main size of installation is American standard size, which is suitable for the North American customers.

8. Technical parameters and installation dimensions are same as the Auburn Gear's Model 3, Model 4, Model 5, Model 6, Model 6B, Model 7, Model 7B, Model 8, Model 8B, and Model 9, which can be replaced with them also.

Alternative Brand/Model