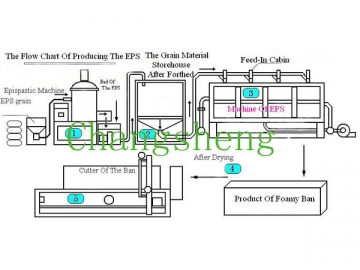

EPS Production Line

Main Features

1. The EPS production line uses a PLC and touch screen control, making it easy to control. It requires no maintenance, and features a high degree of automation.

2. The mold can open and close, and the material feeding, heating, heat preservation, cooling, vacuum cooling, demolding, and ejection can be carried out with either semi-automatic or automatic settings.

3. The machine uses air cooling methods, suitable for low density blocks. The formation time is fast, and the moisture content is low.

4. The machine uses an intense heating and exhaust duct, which saves stem, and heats in a uniform manner. This speeds up the formation time.

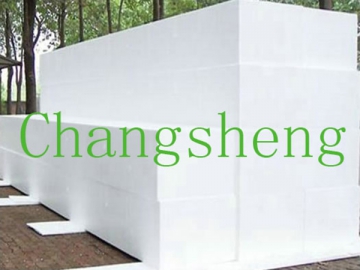

5. The machine uses advanced block making technology to control the heating of all sides, ensuring the precise dimensions of the blocks.

6. The EPS block forming machine is welded from high profile steel, and through a heat treatment, ensures the strength of the machine without deformations and the possibility of an expansion force of high density and thick blocks.

7. The surface of the block forming machine cavity uses a high quality aluminum alloy plate and is coated in Teflon. This makes it easy to remove the mold and ensures the excellent finish on the block as well as the long service life. The machine uses a large feeding gun for feeding material at a faster feeding speed than other machines.