EPS Sandwich Panel Machine

EPS Sandwich Panel Machine XBJ

Our EPS sandwich panel machine is the forming equipment that integrates the state-of-the-art mechanical, electrical, pneumatic and chemical technologies. This automatic production line is increasingly used in the construction of steel structure enclosures, cold storages and mobile buildings. We manufacture this sandwich panel machine in various specs and configurations to meet your specific requirements.

Main Components

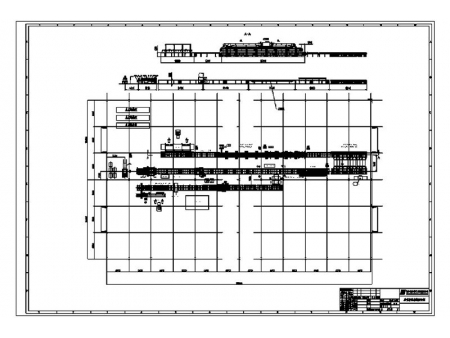

Jinggong EPS sandwich panel machine is mainly composed of a decoiler, feeder, film covering system, roll forming machine, laminating system, spraying device, heater, cutting equipment, conveyor, electric control system, and pneumatic system.

| Item | Parameter | Remark | |

| Suitable panel materials | Type | Color coated steel plate, aluminium plate | |

| Plate strength | ≤350 MPa | ||

| Plate thickness | 0.4-0.8 mm | ||

| Plate width | ≤1200 Mm | According to the shape of panel | |

| Coil inside diameter | 500, 600 mm | ||

| Coil weight | 5 T | ||

| Suitable core materials | Rock wool, EPS | As per customers' requirement | |

| Panel length | 3-15 m | ||

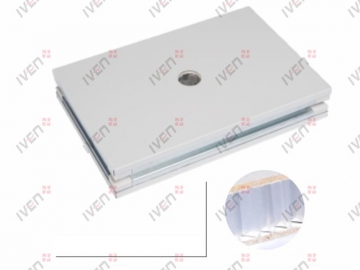

| Panel width | 950-1200 mm | According to the shape of panel | |

| Panel thickness | 50-250 mm | ||

| Working speed | 1-3 m/min | Adjustable | |

| Electric control system | Industrial computer PLC frequency control | ||

| Length of compound part | 7.5 M | According to design requirement | |

| Total power | About 42 Kw | ||

| Outline dimensions (LXWXH) | 40X3.6X3.3 m | ||

Jinggong Science & Technology is an EPS sandwich panel machine manufacturer and supplier with over 50 years of experience. We provide a wide variety of high-quality construction material machinery, such as roll forming machine, steel deck forming machine, and guardrail forming machine etc. Our products have earned the ISO9000 and CE certificates, and are well received in America, Australia, Bulgaria, Argentina, Egypt, India, and more. Contact us today for more information!

Product application