PVD Coating Equipment (for Glass Mosaic and Glass Products)

Request a Quote

If most of your coating work involves glass, then this PVD coating equipment will meet your needs. At the heart of this vacuum coater is a magnetron sputtering system that uses pulsed power supplies to ionize the target (solid metal) and ensure optimal deposition uniformity. Other than glass, the PVD coating equipment also works perfectly on plastics, ceramics, resins, and various other building materials.

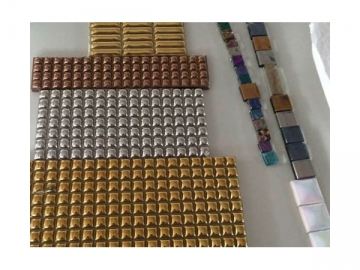

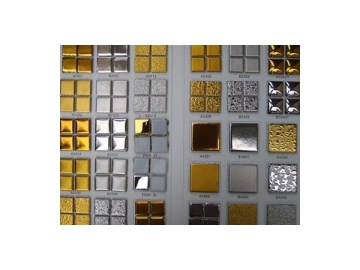

Colors of Coating

Gold, silver, red, antique bronze, black, blue, etc.

Benefits of PVD Coating Equipment

Using one or multiple magnetrons, the PVD coater creates high energy electrons and directing them to hit the target so hard that atoms in that target are energized and rush towards the substrate waiting to be coated. Magnetron sputtering improves deposition adhesion, density, uniformity and repeatability. Coatings include copper, titanium, chromium, stainless steel, and nickel.

| Model No. | ||||

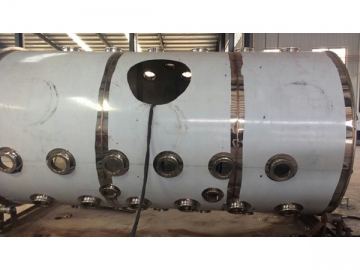

| Vacuum Chamber Size | ф1200×1500 | ф1500×1700 | ф1700×2000 | ф2000×2360 |

| Air Pumping Speed | 1×105 Pa~3×10-3 Pa≤20min | |||

| Maximum Vacuum Level | ≤1×10-3 Pa | |||

| Auxiliary Equipment | KT-630×2 /2X-30 /H-150X2 (ZJP-300×2) | KT-800×2 /2X-30 /H-150X2 (ZJP-600×2) | ||

| Transmission | Planetary Gear (for rotation and revolution). Number of rotary shafts: 8, or as per customer requirements ) | |||

| Heating Method | Stainless steel tubes are mounted to the side of the vacuum chamber. | |||

| Ion Bombardment | DC 1000V | |||

| Gas Supply System | Flow rate controller controls the speed of gas flow into the vacuum chamber. | |||

| No. of Targets | 20 | 25 | ||

| Working Mode | PLC semi-automatic control or PC PLC fully automatic control | |||

| Operating Gas | Ar , N2, O2, C2H2 | |||

| Total Power | 120KW | 160KW | ||

| Compressed Air Pressure | 0.4~0.8MPa | |||

| Water Cooling System | Water Pressure/Water Temperature: ≤25 ℃ /≥0.25MPa (Prepared by customers.) | |||

Related products

Send Message

Most Recent

More

Other Products

Videos

.jpg)