PVD Coating Equipment (for Stainless Steel Sheet and Pipe)

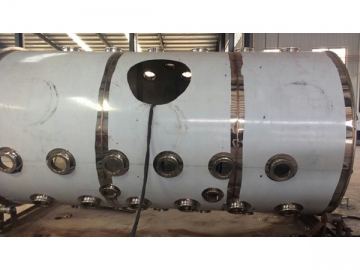

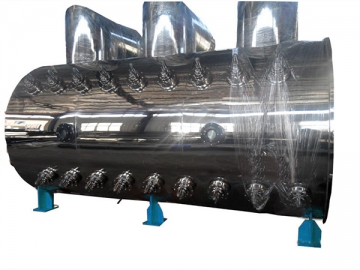

The vacuum coating created by our PVD coating equipment has the feel of real metal which is unmatched by any other type of coating developed via the CVD process. The vacuum chamber stands 3600mm to 6500mm high, with a diameter ranging from 1800mm to 3200mm.

Stainless Steel Grades

The multi-functional PVD coating equipment can handle a variety of steels, including SUS304, 316, 316L, 430, 439, and 443.

PVD Coating Colors

BITE's line of PVD coating equipment can create a variety of colors, such as gold, silver, gun black, black, rose gold, coffee brown, rainbow (7 colors), blue, etc.

Applications of PVD Coating System

A variety of materials can be coated with our PVD coater, including furniture, luminaire, automobile, aerospace, and metal hardware.

Features of PVD Coating Machine

1. Comes with 3 vacuum pumps that quickly empty the vacuum chamber of any air for faster cycle times.

2. Targets in round shapes are properly arranged and equipped with a bias voltage pulsed power supply. The resultant film forms a tight bond to the substrate and ensures color uniformity across the substrate surface.

3. User-friendly touch screen, plus advanced PLC, allows easy switch from manual to automatic mode and vice versa. Computerized control system ensures reliable, stable performance.

| Model No. | | ||||||

| Vacuum Chamber Size | φ1800 x2000 | φ2000 x2000 | φ3000 x3000 | φ2000 x6000 | φ3000 x6000 | φ4000 x8000 | φ5000 x10000 |

| Vacuum Chamber Parts | Vertical door, lifting or trolley mechanism, water cooling system, air suction system | ||||||

| Vacuum Pump | Mechanical pump + Roots pump + Diffusion pump/Molecular pump + Appendage pump | ||||||

| Pirani gauge (MKS), cold cathode (MKS), diagram gauge(MKS) | |||||||

| Vacuum Coating System | Cathodic arc source, power supply | ||||||

| Gas Supply | Mass flow meter | Mass flow meter | Mass flow meter | Mass flow meter | Mass flow meter | Mass flow meter | Mass flow meter |

| Power Supply Type | DC power supply, mid-frequency power supply, pulsed power supply (bias voltage power supply, arc discharge power supply) | ||||||

| Maximum Vacuum Level | 5.0x10-4 Pa | ||||||

| Arc Discharge Power Source | 22sets-28 sets | 22 sets -28 sets | 26 sets -32 sets | 26 sets -32 sets | 32 sets -48 sets | 32 sets -48 sets | 32 sets -48 sets |

| 200A -300A | 200A -300A | 200A -300A | 200A -300A | 200A -300A | 200A -300A | 200A -300A | |

| Bias Voltage Power Supply | 60KW /set | 60KW /set | 70KW /set | 70KW /set | 80KW /set | 80KW /set | 80KW /set |

| Magnetron Power Source | -- | -- | -- | -- | -- | -- | -- |

| Transmission | Planetary gear (rotation, revolution) powered multiple shafts, VFD (for speed adjustment and control) | ||||||

| Operating temperature | Ambient- 450 ℃ (PID temperature controller) | ||||||

| Gaseous Environment | 3 or 4 gas circuits with flow control and display. Optional gas pumping system | ||||||

| Argon, nitrogen, oxygen, acetylene, etc. | |||||||

| Cooling Method | Circulating water system (industrial cooling tower, industrial water chiller, or cryogenic system). Prepared by the customer. | ||||||

| Control Method | PLC Touch Screen or Computer Control, manual, semi-automatic, automatic | ||||||

| Working conditions | Air pressure: 0.5-0.8MPa, water temperature≤25 ℃ , water pressure≥0.2MPa | ||||||

| Alarm and Protection | Water shortage, overflow, over -pressure, short-circuit warning alarm, complemented by electrical interlocking control and protection. | ||||||

| Total Power | 165- 185KW | 185- 200KW | 200- 225KW | 225- 245KW | 245- 265KW | 265- 300KW | 265- 300KW |

| Output Power Supply | Voltage: 380V±5%, Frequency: 50HZ (Can be customized according to power supply standard in client country.) | ||||||

| Footprint | 25~55m2 | 35~55m2 | 35~55 m2 | 45~55 m2 | 45~55 m2 | 55~75 m2 | 55~75 m2 |

| Note | Above data are used for reference only. | ||||||

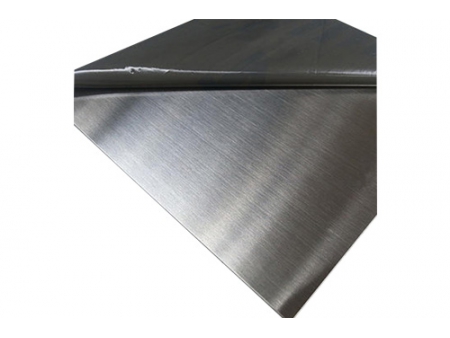

PVD Coating Samples

.jpg)