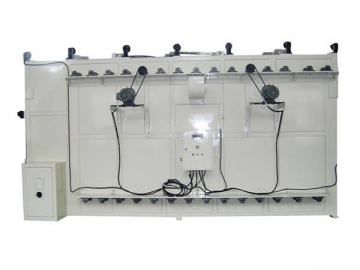

Drying Oven for Printed Tinplate

Model: SJF

Our drying ovens specialize in printing, coating, drying cooling, unloading and collecting sheet metal for can manufacturing.

Our tin plate drying oven can be heated using city gas, natural gas, liquid gas, kerosene, light diesel oil with a viscosity of 1.5 Engler, coal, and electricity. Our printed tin plate drying ovens are applicable to a variety of sheet metals with different specifications and different uses.

Advantages

The front and back transmissions of our can making equipment are enclosed. The protection device for unloading, the conveyor chain tensioner, the calibration device for unloading, and the calibration device for the stacker are all pneumatically controlled.

Synchronization is achieved using frequency control. There are suction and magnetic cushion devices in the loading section of our tin plate production line. The heating of the fuel includes both direct and indirect combustion.

| Max. Drying Speed | 6,000 sheets/ hour |

| Max. Drying Temperature | 230℃ |

| Length of Oven | 27 m |

| Total length of Oven | 42.95 m |

| Drying Time in Drying Zone with Constant Temperature | 4,800 sheets/ hour:10 minutes |

| 5,100 sheets/ hour: 9.4 minutes | |

| 5,400 sheets/ hour: 8.9 minutes | |

| 6,000 sheets/ hour: 8 minutes | |

| Max. Sheet Size | 1,150×965mm |

| Min. Sheet Size | 710×508mm |

| Sheet Thickness | 0.15-0.4mm |

| Fuel | Gas LPG |

| Cooling Zone | 5.48 m |

| Quantity of Heating Chamber | 2 |

| Air Intake Volume in Cooling Zone | 50,000 m 3/hr |

| Air Outlet Volume in Cooling Zone | 55,000 m 3/hr |

| Air Supply | ≤4500 m3/hr |

| Air Volume of Front Exhaust | Approx.10,000 m3 /hr |

| Air Volume of Rear Exhaust | Approx.4,000 m3 /hr |

| Total Power Consumption | Approx. 45.45kw |