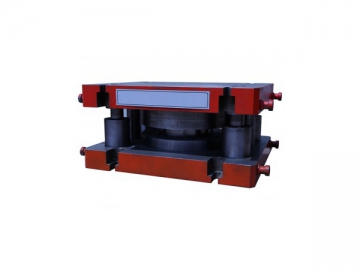

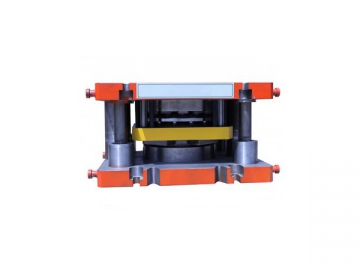

Tooling for Wheel Spoke Manufacturing

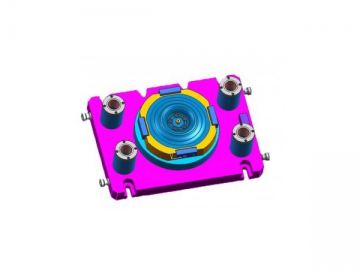

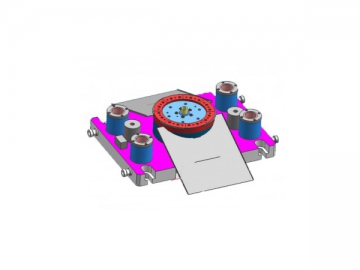

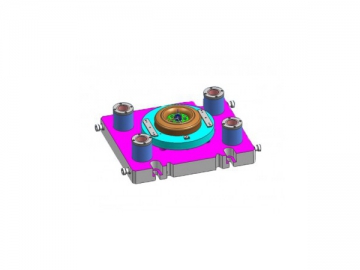

XIAOYA specially developed dies for high strength plate wheel spokes that are suitable for use on automatic spoke stamping lines. According to production processes, including wheel spoke forming, punching, and reshaping, 7 primary sets of dies are involved as follows:

- Blanking-punching Compound Die

- Forming Die

- Forming Die

- Flanging Die

- Piercing Die

- Air-hole Deburring Tool

- Screw-hole Reshaping Die

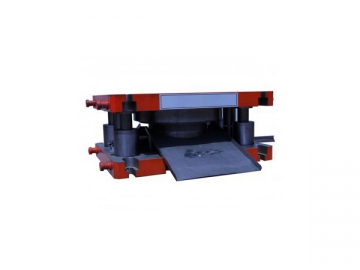

In order to satisfy the requirements for stand-alone operations in traditional wheel spoke production lines, XIAOYA carries out personalized process designs and die structure designs according to customer product structures and equipment condition. Traditionally, a traditional spoke production line consists of 9 processes: blanking-punching, initial faring, forming, trimming and punching, flanging, screw-hole punching, screw-hole deburring, air-hole punching, and air-hole deburring. The following display some of the dies used in the above processes:

- Disposable air-hole punching die

- Screw-hole punching die

- Forming die

- Profiling die

- Compound punching die

- Assembly press die