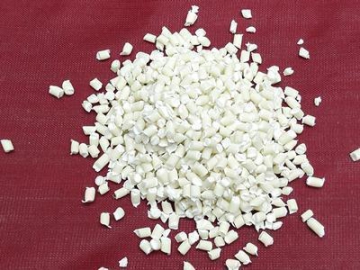

Antistatic Additive Masterbatch

Features

1. Customers can choose the corresponding anti-static additive masterbatch according to their own unique plastic materials. We encourage our customers to test the additive masterbatch amount according to the recommended additive amount in order to confirm the effects and determine a reasonable and economic added ratio.

2. Special instruction: Plastic products with an anti-static master batch will have an anti-static effect only when the anti-static agent has migrated to the surface of the plastic products- a process that takes time. If the plastic product is tested immediately after production, the change for errors is significantly high. To avoid this, wait 24 hours after production, then carry out the test for a more accurate effect. The anti-static effect of the products is also related to the storage and usage environment, with the best performance being found in wet environments.

3. Packaging and storage: Three-in-one compound bag, 25KG/ bag. This bag is moisture absorbent, so the bag should be stored in a dry environment so as not to effect the stored additive.

Practical significance

Plastic is a material known for its high performance and is widely used in most aspects of daily life, as well as in industrial production. Plastic material generally has a high insulation rate, with a surface resistance of about 1 x 1013-1016 Ω, making it easy for static to collect on the surface. In the processing and usage of plastic, static also gathers and creates physical signs, such as plastic granules, or products that will absorb dust, or making it difficult to open film, difficulty printing or coating, and electric discharge through friction. In rare cases, it can lead to dangerous sparks, which in turn can lead to a risk of explosion. All of these factors affect both production and application of plastic. Add an anti-static masterbatch, and the anti-static agent will gradually migrate and accumulate on the plastic surface, making it active and hydrophilic so as to adsorb water and moisture in the air, which then forms a conductive layer on the surface of the product in order to reduce the resistivity and accelerate static removal. If added properly, the resistivity of the surface will be reduced by as much as 103 or 104 times.

Index

plastic masterbatch, master batch, polymer, plastic additive