Flame Retardant Additive Masterbatch

Introduction

Flame retardant additive masterbatches use a carefully formulated, efficient and environmentally friendly flame retardant additive. They are suitable for use in ABS, HIPS, PP and PE materials, giving them not only a great flame resistance, but also an excellent dispersibility and affinity with matrix resins.

Application

The flame retardant masterbatch is widely used in adding a flame retardant coating and color to different products, ranging from light to dark. Some of these products include communication cables, electric wires, instrument shells, distribution boxes, wiring pipes, refrigerator parts, electrical switches, conduits, electrical enclosures, PE coated paper, plastic nets, PP woven bags, PS acrylic light diffuser sheets, plastic doors and windows, panels and more.

Function

Based on the performance and processes of PE, a series of polyethylene flame retardant masterbatches have been created, including drawing class, extruding class, film class, coating class, antistatic class and more, and are an ideal replacement for powdery flame retardants. These masterbatches also feature a high concentration, excellent dispersibility, and high cost performance, all while simplifying the production process, thus making them great for meeting the needs of different products.

Technical index

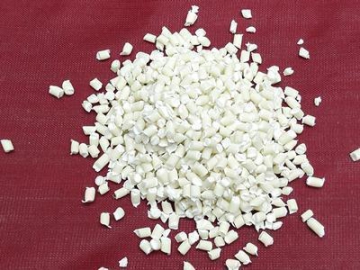

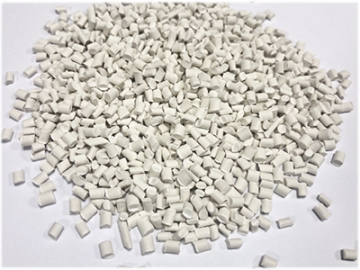

Appearance: It is cylindrical and grainy. Its diameter is about 4mm, length is about 4mm.

Flame resistance: V-0.V-1.V-2.HB grade

Migration resistance: ≥ 4 grade

Recommended ratio: 1:3, 1:20 (It depends on requirements for flame resistance and the variety of resin)

Practical significance

The flame retardant additive masterbatch has become increasingly popular in the plastics industry in recent years due to continuous improvements upon the requirements for the flame resistance of plastic products. We choose high quality flame retardant materials and related formulations from both at home and abroad. In the process, several types of flame retardant additive masterbatches produced by us have been approved by UL in America, and found a stable market in the plastic industry both at home and abroad. We can also supply a color matching service for customers if they are using our flame retardant additive masterbatches, thus ensuring the product's top quality.

Usage

1. Customers can choose the correspondent flame retardant masterbatch to their plastic materials, and sample it based on the recommended additive amount. After confirming the request, there will be a formal determination of the official added ratio of the same material.

2. Add the flame retardant masterbatch to ABS material and mix it. After the mixing, the drying processes should be done together. This treatment is similar to original ABS material.

3. The masterbtach is produced using two different types of flame retardant materials through a mechanical mixing and granulating process. The leading flame retardant materials and the cooperative materials will therefore perfectly combine. Though plastic products that have been just produced will meet flame retardant requirements, their effectiveness will be different from those produced 6 months to a year earlier. Over time, the flame retardant effectiveness increases, meaning those produced 6 months to a year earlier feature better flame retardant capabilities, as demonstrated by experiences shared by both us and our customers.

4. This data and all relevant data are not universal in application and are used only for reference. They should not be regarded for a legal basis, though we do guarantee that the performance of each batch is consistent.

5. Packaging and storage: Three-in-one compound bag, 25KG/ bag

Index

plastic masterbatch, master batch, polymer, plastic additive