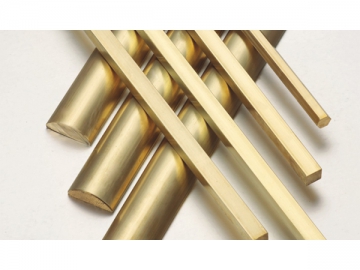

Complex Brass (with High Corrosion Resistance)

Categories: Bar & Wire production-Brass Alloy Material

Name: Complex Brass (High strength, high corrosion resistance)

Number: C67420, CuZn38Mn2NiSi, C86300, C67300, C6782

Alloy Features

Good wear resistance;

Excellent corrosion resistance;

High intensity;

Hot forging performance;

Outstanding cutting characteristics;

Self-lubricating performance ;

| Item | Specification | |||

| ASTM | DIN | JIS | GB | |

| C67420 | CuZn37Mn3Al2PbSi(CW713R) | - | HMn59-2-2 | 5.0-120mm |

| C67300 | - | - | - | |

| - | CuZn38Mn2NiSi | - | - | |

Characteristics

Manganese brass, with high strength, high wear resistance and corrosion resistance.

Application

Widely used in auto, hydraulic pressure and machinery manufacturing industries. Primarily used to construct auto synchronizer ring gears, turbochargers, bearings, shaft sleeves and gears.

| Item | Specification | |||

| ASTM | DIN | JIS | GB | |

| C86300 | DIN1709 G-CuZn25Al5 | - | (HAl64-5-4) | 5.0-120mm |

Characteristics

High hardness, high strength, high abrasion resistance, high corrosion resistance

Application

Widely used in the standard die-part industry

| Material | Articles | Chemical composition (wt%) | ||||||||

| Cu | Al | Fe | Mn | Ni | Si | Sn | Zn | Other | ||

| Complex Brass | CuZn37Mn3Al2PbSi (CuZn40Al2) | 57 -59 | 1.3 -2.3 | ≤1.0 | 1.5 -3.0 (1.6 -2.6) | ≤1.0 | 0.3 -1.3 | ≤0.4 | REM | ≤0.3 |

| Temper | Specification | Tensile Strength (Rm N/mm2) | Yield Strength (Rp0.2 N/mm2) | Elongation (A% ) | Hardness (HB) |

| R590 | 5mm -120mm | ≥590 | ≥320 | ≥12 | ≥160 |