Industrial Blade (Slitter Blade used in Sheet Metal Slitting Machine)

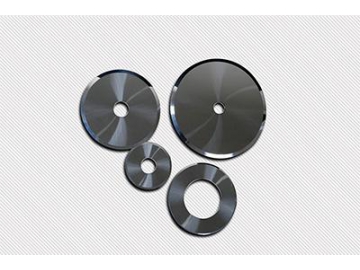

If you are in the sheet metal or coil slitting business looking for quality slitter blade, then you are at the right place. We at HENGLIDA provide wear-resistant slitter blade used in sheet metal slitting machine. Because of the constant metal on metal contact between the upper slitter blade and lower blade, these blades need to be tough enough to resist wear and tear. That is why we use 9CrSi, Cr12MoV, 6CrW2Si, H13, H13K, LD, high-speed steel, and hard alloys to construct the industrial blade which has also been subjected to heat treatment and sub-zero cooling to ensure uniform hardness.

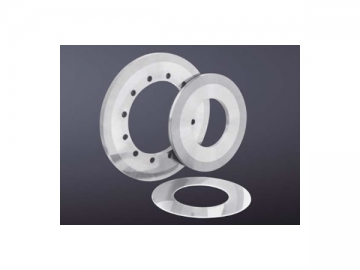

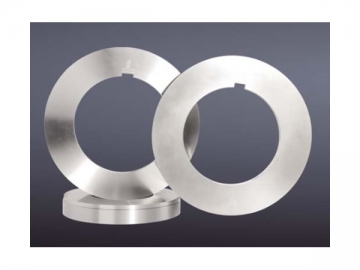

A smooth, sharp cutting edge has made HENGLIDA slitter blade a real eye-catcher. The circular knife works best on sheet metals and metal coils, cutting them lengthwise into narrower strips or rolls. For ordinary slitting jobs, a circular slitting blade with diameter below 1.2m is enough though high-precision circular blade with diameter below 0.5m is also available. Unique vacuum heating, sub-zero cooling and grinding allow tight tolerances to be held during manufacture.

Thickness Tolerance: ±0.001mm

Surface Flatness: 0.002mm

As a matter of fact, the cutting head of a slitting machine includes many other parts than the circular slitting knife, such as rubber gasket and spacer. Typical uses of the circular knife includes in large-scale steel plants, steel tube plants, non-ferrous metal factories, packaging materials factories, baling materials factories, cold rolling factories, steel plates processing service center, strip steel plants, slitter factories, and steel mesh factories.