Powder Feeding & Conveying System

Request a Quote

Bag Dump Station

Bag dump station is suited for emptying of small volume bags ofpowder orparticles in a dust-free manner, widely used in a variety ofindustriesincluding pharmaceutical, food processing, fine chemistry andotherindustries.

Features

- Entirely made of stainless steel, simple and robuststructure;

- Negative pressure dust collection, efficiently preventingspreadingof dust;

- Equipped with screen and vibrating unit, ensuring thatmaterialflows smoothly;

- Easy to operate, fast handling capacity;

- Output: 1500kg/h-2500kg/h

- Power: 1.5kW (380V/50Hz)

- Air Consumption: 1500 m³/h

Dust-free disposal inline dispersion

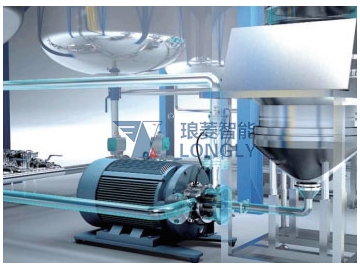

Vacuum Conveyor

Vacuum conveyor is mainly designed for conveying powder orparticles insectors of food, pharmaceuticals, chemical products and otherindustrieswhere high degree of safety and hygiene is critical.

Features

- Built in a simple structure, easy to disassembly andassembly;

- Negative pressure conveying, no air leakage, ensuring highefficiency;

- Individual design of back-flushing, allowing material to beflowedsmoothly;

- Fully automatic control, easy to operate.

Specifications

| Model | Throughput (KG/H) | Vacuum Pressure (kPa) | Motor Power (kW) | Air Pressure (mPa) | Air Consumption (L/Min.) |

| LGZW-10L | 600 | -40~-50 | 3 | 0.4-0.6 | 10 |

| LGZW-20L | 1200 | -40~-50 | 4 | 0.4-0.6 | 10 |

| LGZW-30L | 2000 | -40~-50 | 5.5 | 0.4-0.6 | 12 |

| LGZW-40L | 3000 | -40~-50 | 7.5 | 0.4-0.6 | 2 |

Vacuum Conveying

Dosing System

Dosing system is used to automatically weighing and dosing ofpowder orparticles for industries including pharmaceutical, foodprocessing, finechemistry, etc.

Features

- Materials transferring and dosing processes are accomplishedin afully enclosed structure, ensuring a dust-free processing;

- PLC system or computer control, automatic implementing ofweighingand dosing according to specified recipe;

- Automatic data collecting, ensuring high accuracy ofmaterial typeand weight;

- No need for manual intervention in the dosing area, greatlyreducingmanufacturing cost;

- Fasting dosing, high efficiency, energy saving andeco-friendly;