The KJ310 hydraulic tunneling drilling rig was specially engineered to operate in extremely inclined tunnels with a maximum slop of 25°. It is qualified for the drilling of hard-rock in mines with sections in the range of 12-35 square meters.

Features

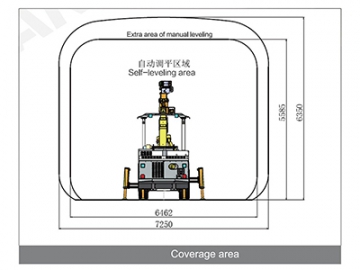

1. The firm flexible boom is capable of optical coverage of the section; 360° rotation and self-leveling beam make drill positioning easy. The boom can also be used for the drilling of lateral cross-cut and rock bolting.

2. The drill rig is capable of advancing the beam’s translation, automatic suspension of drilling of end hole, slag blowing at the hole bottom and electronic impulse lubrication, improving drilling efficiency;

3. The stepped piston is used for the high-frequency impacting rock drill and this can improve the transmission efficiency of the impact wave and drilling speed and reduce the consumption of drilling tools.

4. Considerable space and automatic functions enable the driver to concentrate on drilling in a safe, fast and accurate manner.

5. The drill rig provides a good view for the operator. All the relevant parts are kept in good protection, meanwhile maintenance easily.

Technical Parameters

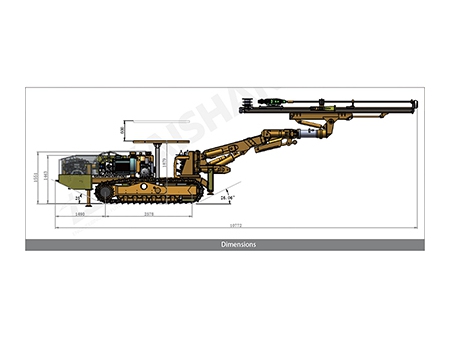

1. Dimensions and weight | Length | 10700mm |

| Width | 1650mm |

| Height | 1900/2500mm |

| Weight | About 12000kg/Appr. 12000㎏ |

| Tramming speed on flat ground | 2.5km/h |

| Maximum climbing capacity | 25° |

2. Safety protection | Noise level | <100dB(A) |

| Lifting safety roof | Meet the requirements of FOPS and ROPS |

3. Air & water system | Air compressor | 1*JN5 | Oil Consumption of lubrication | 180-250g/h |

| Capacity of air compressor | 0.5m³/min |

| Pressure | 6-8bar | Water pump | 1xCR3 | 1xCR5 |

| Device of shank lubrication | Electronic pulse lubrication pump | Power | 1.5kW | 5.5kW |

| Air consumption of lubrication | 0.3m³/min | Capacity of water pump | 3m3/h | 6m3/h |

4. Chassis | Diesel engine | Cummins QSB3.9-C80-31

60KW,2200rpm | Parking braking | Wet multidisc brake |

| Exhaust purification | Exhaust catalyst | Travelling braking | Wet multidisc brake |

| Drive system | track travelling driven by double-speed motor | Fuel tank | 30L |

5. Drilling system/Electric hydraulic power unit | Rock drill | 1×HC50/R38 | 1×HC109/R38 | 1×HC95LM/R38 |

| Impact power | 13kW | 18.8kW | 21kW |

| Impact flow | 105L/min | 135L/min | 100-120L/min |

| Impact pressure | 130bar | 135bar | 180bar |

| Maximum rotary pressure | 150bar | 150bar | 210bar |

| Impact Frequency | 62Hz | 47Hz | 62 Hz |

| Torque | 325Nm | 780Nm | 764Nm |

| Hole diameter | Φ32-76mm | Φ42-102mm | Φ42-102mm |

| Beam rotation | 360° |

| Feed extension | 1600mm |

| Model of drill boom | K 26F |

| Form of drill boom | Self-leveling |

| Boom extension | 1200mm |

| Motor | 45kW | 55kW | 75kW |

| Impact /Feed/ Positioning | Axial variable displacement piston pump |

| Rotation | Gear pump |

| Filter fineness | 10µ |

| Hydraulic oil tank | 240L |

| Hydraulic cooler | Water cooler |

| Working voltage | 380V |

| Frequency | 50Hz |

| Starting method | Star-triangle |

| Cable reel | 1*F440 |

| Length of reel cabling | 100m | 80m |

| Outer diameter of cable | Φ28mm | Φ32mm |

| Cable specifications | 3×35 3G6 | 3×50 3G6 |