Flatbread Line

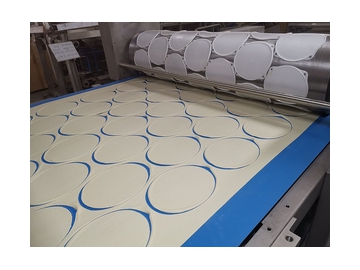

This processing table only is the forming table to produce thin bread base with<45% water content. Different necessary machine units can be added on the line to make round tortilla dough, pizza disk with holes or edges, lavash, naan, chapatis, roti and pita base and ect.

This line is able to be connected with proffer, tunnel oven and cooler to meet clients’ integrated production requirements. High output, nice work performance and stable product weight are its attractiveness to certain food manufacturers who are particular with the machine quality.

- Different size and shape product can be produced on the same line.

- Equipped with Video monitoring equipment, easy to watch the running situation of main part to reduce the downtime.

- Abnormal data can be found and optimized by the remote control system.

- Thickness can be adjusted automatically. One-click switching of multiple products’ production can be achieved by saving formula.

- Durable 304 stainless steel structure and high food grade PU conveyor belt.

- Each machine unit has a cover plate that can be opened quickly for easy cleaning.

- Each transmission and connection link of the line are equipped with scrapers and dough scrap collection boxes to keep the equipment and the ground clean.

- Forming Table

- Cross Sheeter

- Ideal Dough Band

- Proffer/ Rest Station

- Rotary Cutter

- Dough Scrap Collection

- Entering the Oven

- Tunnel Oven

- Cooler

Dough hopper& extruder – Satellite – Cross sheeter – Gauging station 1 - Gauging station 2 – Flour brusher – Forming table – Dough scrap collection unit – Tunnel oven – Cooler – Flow pack machine

Note: Production processing, dough band width and thickness are able to be designed based on the real needs.

| Industrial output | Max. ≤14000pcs/h |

| Belt width | 650mm |

| Dough band width | ≤600mm |

| Thickness range | 1mm-10mm |

| Power | 15kw |

| Linear speed | ≤9m/min |

| Product shape | Round, square, and other customized shape |

| Line type | Straight |

| Line size | L 14m* W 2.5m* H 2.2m |

| Machine weight | 5000kg |