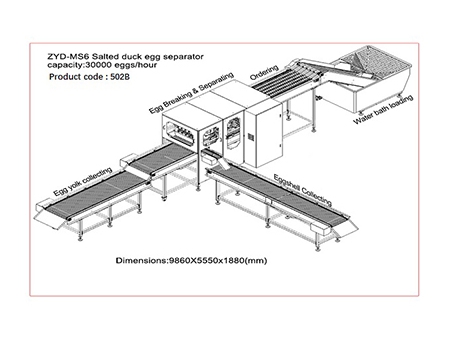

502B Salted Duck Egg Separator

This egg separator is designed for separating duck eggs and integrates various functions including water bath loading, egg ordering, egg breaking, separating yolk and egg white, etc. It is made of 316 stainless steel and meets the food safety standards. Pour an entire tray or box of duck eggs into the water bath, where a conveyor will then carry the duck eggs to the entrance of the spinning plate in six feeding lines with the use of a roll-type slope egg feeding device. The egg white, yolk, and eggshell will flow into separate channels for manual collection. This machine has a maximum capacity of 30,000 eggs/hour. It is convenient to use and can help you save labor and time.

Salted duck egg separator

| Model | ZYD-MS6 |

| Product code | 502B |

| Capacity | 30,000 eggs/hour |

| Power* | 3KW, 50HZ |

| Voltage* | 380V, 3-phase |

| Length* Width* Height | 9.86*5.55*1.88 M |

| Net weight* | 1000 kg |

| Gross weight* | 1500 kg |

| Functions | Water bath loading, ordering, Egg Breaking, Egg Yolk Separating from Egg White |

- Water bath loading

- Egg ordering

- Egg breaking

- Egg separating

- Egg white, egg yolk and egg shell collecting

manually pour an entire tray or box of duck eggs into the water bath.

The rubber rollers adjust the position and posture of the duck eggs by rolling and send them to the entrance of spinning plate.

The spinning plates with blades catch the duck eggs from the conveyor and split them evenly from the bottom.

The grippers catch the duck eggs and separate the yolk and egg white from the incision.

the egg white, yolk, and eggshell will flow into separate channels for manual collection.