GKH Siphon Peeler Centrifuges

The GKH siphon peeler centrifuges are practically engineered on the basis of common horizontal scraper centrifuges.

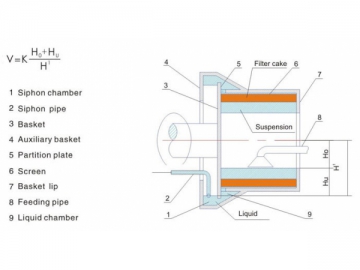

Siphon Principle

With the adoption of siphon principle, more pushing force is generated to assist all clarified liquid to pass through filtration media into liquid chamber. Then liquid is drained out of basket via siphon. Suction inlet placement determines liquid level in suction chamber, thus leading to changes of pushing force, filtration speed, handling capacity, cake dryness and washing efficiency.

Recoil device is available to supply washing liquid to suction chamber when it’s needed. Washing liquid flows through filtration media into basket, whereby refreshing filtration function.

Main Features of GKH Siphon Peeler Centrifuge

1. Feeding

Due to free adjustment on filtration speed, lower filtration speed is recommended for feeding progress, thus bypassing problems of un-even distribution of cake.

2. Filtration

Siphon pipe locates at low level in filtration stage. With column height Hu of additional liquid, filtration speed swells and processing capacity in amplified by 50%.

3. Washing

Suction inlet of siphon pipe locates at high level during washing stage, offering quite small pushing force. Therefore, washing liquid moves slowly, resulting in prolonged time of remaining in cake, minimized washing liquid consumption and better washing effects.

4. Dewatering

In this period, suction inlet of siphon pipe is deployed at the lowest level, generating the largest pushing force. As a result, water contained in cake can be readily drained out.

5. Backwashing

After scraper discharging, washing liquid can be added into siphon chamber from outside. The washing liquid flows through filtration media into basket for backwashing, which brings exceptional washing effects and regeneration ability to filter cloth.

Main Application of GKH Siphon Peeler Centrifuge

This starch separation equipment is highly recommended for applications where requiring large volume production, high cake dryness and remarkable washing effect. Therefore, our enclosed centrifuge is applicable for separation of starch, sodium bicarbonate and calcium phosphate, etc.

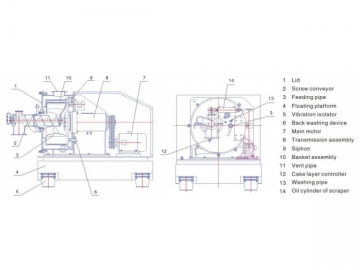

Structure of GKH Siphon Peeler Centrifuge

Starch Processing Capacity and Centrifugal Force (For Reference)

| Item | Productivity (t/h) | Moisture content (%) | Solid-phase Material Loss (%) |

| GKH800 | 0.8-1.2 | 35-38 | 0.05 |

| GKH1000 | 2.0-2.5 | 35-38 | 0.05 |

| GKH1250 | 3.5-4.5 | 35-38 | 0.05 |

| GKH1600 | 8.0-10 | 35-38 | 0.05 |

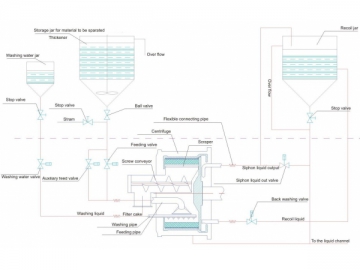

Workflow of GKH Siphon Peeler Centrifuge(For Reference Only)

Technical Parameter of GKH Siphon Peeler Centrifuge

| Item | Model | |||

| Basket Dia. (mm) | 800 | 1000 | 1250 | 1600 |

| Basket Length (mm) | 450 | 500 | 625 | 800 |

| Basket Volume (L) | 100 | 172 | 370 | 690 |

| Max. Load (kg) | 135 | 240 | 500 | 930 |

| Max. Speed (rpm) | 1550 | 1350 | 1200 | 950 |

| Centrifugal Force | 1080 | 1020 | 1007 | 808 |

| Motor Power (kW) | 45 | 55 | 90 | 132 |

| Dimension (L×W×H) (mm) | 2550×1850×1350 | 2400×2150×1700 | 3450×3300×2500 | 4550×2750×2300 |

| Weight (kg) | 4000 | 8000 | 12000 | 16550 |