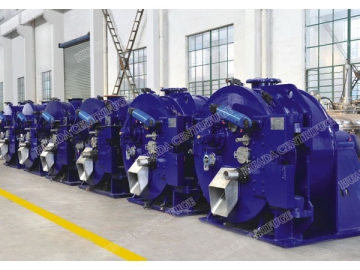

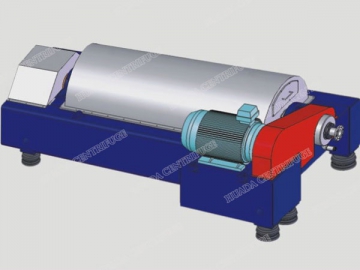

GK Peeler Centrifuges

GK peeler centrifuges are highly characterized by continuous workflow and batch-type operation. Fast switch between manual and automatic operation is available in this separation equipment. Entire workflow of this dewatering equipment can be conducted at full speed including feeding, separation, dewatering, discharge and regeneration of filter cloth, etc.

This peeler centrifuge features short single cycle time and impressive processing capability. Customers avail from outstanding dewatering and washing effects.

Main Features and Optional Configurations of GK Peeler Centrifuge

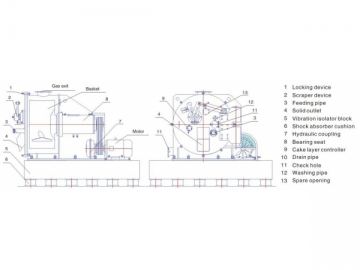

1. PLC system is introduced to explosion-proof horizontal scraper centrifuge for efficient remote control. Touch screen delivers intuitive operation and easy maintenance.

2. Electro-pneumatic/hydraulic control system is applied to moving parts.

3. Multi-protection is available to ensure safety and smooth performance, and falls into rotation speed detection, over-vibration protection. Cover protection, motor overheat and overload protection, as well as electro-mechanical control of scraper.

4. Welded housing of this peeler centrifuge comes with compact structure and remarkable load bearing capacity.

5. Fully sealed structure is made from silicone rubber or fluororubber.

6. Independent hydraulic unit allows for isolated installation and fast maintenance.

7. Driving systems of GK1250 and GK1600 peeler centrifuges involve the utilization of hydraulic coupling, resulting in stable start-up, easy operation and efficient overload protection. Moreover, optional variable frequency drive is also provided to meet diverse speed requirements.

8. Suspended base enjoys rubber vibration absorbing foundation. Liquid damping vibration absorber is also available to deliver exceptional absorbing effects, stable operation and drastically reduced vibration.

9. Two discharge options are offered which are chute discharge and discharge via scroll conveyor and scraper. The first option is renowned for simple structure, while the second mode features prominent residual cake remove and minimized jam.

Main Applications of GK Peeler Centrifuge

Our peeler centrifuge has been widely applied to industries of chemical, food, light industry and pharmacy, etc. This explosion-proof peeler centrifuge is well-suited for slurries containing large, medium and fine particles such as ammonium sulfate, ammonium bicarbonate and PVC, etc.

Structure of GK Peeler Centrifuge

Technical Parameter of GK Peeler Centrifuge

| Item | Model | |||

| Basket Dia. (mm) | 800 | 1000 | 1250 | 1600 |

| Basket Length (mm) | 450 | 500 | 625 | 800 |

| Basket Volume (L) | 100 | 172 | 370 | 690 |

| Max. Load (kg) | 135 | 240 | 500 | 930 |

| Max. Speed (rpm) | 1550 | 1350 | 1200 | 950 |

| Centrifugal Force | 1080 | 1020 | 1007 | 808 |

| Motor Power (kW) | 30 | 37 | 55 | 90 |

| Dimension (L×W×H) (mm) | 2550×1850×1350 | 2400×2150×1700 | 3450×3300×2500 | 4200×2750×2300 |

| Weight (kg) | 3500 | 7300 | 9000 | 15000 |