Forgings for Shipbuilding

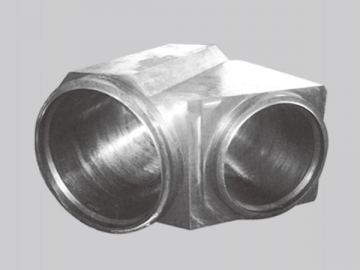

The large forgings for shipbuilding TongYu provides can be divided into 2 types: structural parts of ships (rubber stock,rudder pin), and shaft forgings (intermediate shaft, propeller shaft). The first type mainly calls for high welding, but little carbon equivalent requirements for steels.

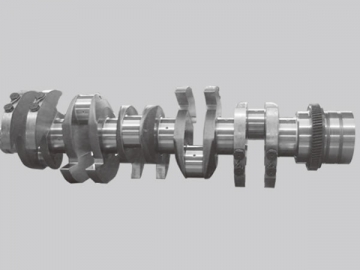

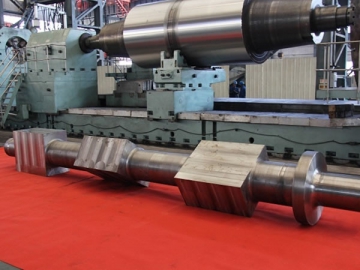

Large crankshaft for ships

3-throw crankshaft

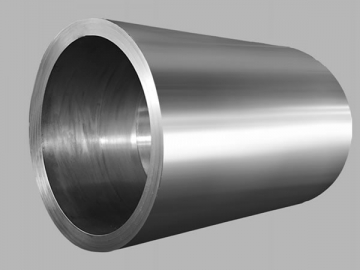

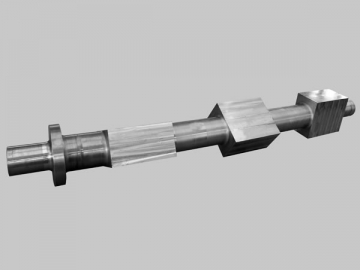

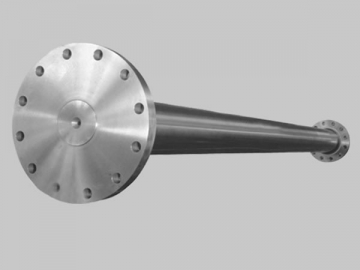

Intermediate shaft

Stern shaft

Forgings for ships feature large size and heavy weight. Its performance requirements, especially property difference between both ends of the boats is extremely harsh. Boats operating in ice-filled waters require additional resistance to low-temperature impact.

In the whole production lines of smelting, forging, heat treatment, flaw detection, and mechanical processing, TongYu has set strict quality control system. The forgings for shipbuilding made by TongYu comply with the rules of the classification societies of each country. We have now been certified by CCS, ABS, BV, DNV, GL, LR, NK, KR, and RINA.

TongYu is now one of the major manufacturers of large castings and forgings. We mainly produce all kinds of free forgings used for thermal power, hydropower, and , etc.

Common Materials

Carbon steel, carbon manganese steel, and alloy steel prescribed by classification societies, like 20Mn, 40Mn, 45Mn, 50Mn, 25CrMo, 42CrMo, and 25Cr2Ni4MoV

Manufacturing Process

Smelting – Forging – Heat Treatment – Roughing – Quenching and Tempering – Machining – Packaging (parts of forgings are well-done after tempering)

Quality Control

1. In the smelting process, to ensure the high purity and low gas content of raw materials, apart from the prescribed chemical elements, we have to strictly inspected some harmful elements such as P, S, Pb, Sn, As, Sb, and Bi, as well as some gas or non-metallic debris like H, O, and N.

2. Strict forging technique is required to meet the nondestructive testing requirements.

3. Heat treatment is needed to enhance the forgings' comprehensive mechanical properties; forgings for boats operating in ice-filled waters are resistant to low-temperature impact.

4. CNC equipment is employed for the finishing line to ensure the forgings' precision.

5. For forging parts with welding needs, we will adjust their chemical components to realize a reasonable carbon equivalent and enhance their performance.

Crankshaft is one of the most important parts in engine. It bears the force passed from connecting level, and transfers it to torque to drive other accessories of the engine. Under the composition of the centrifugal force, the periodically changing inertial force, and the reciprocating inertial force, the crankshaft undertakes bending and torsional loads. The working environment of crankshaft requires it to possess a variety of excellent properties, like strength, rigidness, wear resistance, fatigue resistance, and impact resistance, as well as high dimensional precision. Additionally, the surface, inner structure, and fiber distribution of the crankshaft is vital to its performance.

Large crankshafts used for locomotive and internal combustion engine of ships have to work under harsh environment under heavy load continuously for long time. So the manufacturing requirements for this kind of crankshafts are much higher.

Crankshafts for boats are large and heavy, and complex in structure. It manufacturing process involves many steps, including smelting, ingots fabricating, forging, heat treatment, and machining. So apart from modifying the properties of crankshaft's materials, it is also vital to determine the manufacturing techniques to get the crankshafts with the specific performance we want.

Common materials: 35CrMo, 42CrMo, S34MnV, etc.

Manufacturing Process

Smelting – Forging – Heat Treatment – Roughing – Quenching and Tempering – Machining – Packaging (parts of the crankshafts are well-done after tempering)

Quality Control

1. Apart from the required chemical elements, we have strictly tested some harmful elements such as P, S, Pb, Sn, As, Sb, and Bi, as well as some gas or non-metallic debris like H, O, and N in the smelting process.

2. Strict forging technique is employed both to meet the nondestructive testing needs, and to ensure the continuity of fibers.

3. After being heat treated, the crankshaft will own great comprehensive mechanical properties and high fatigue strength.

4. The finishing line is equipped with CNC equipment to guarantee the high processing accuracy.

Why Choose TongYu Rotors

1. Theship rotors produced by TongYu are distinguished for high strength, fatigue strength and impact resistance.

2. High purity and uniform chemical components

3. TongYu crankshafts are classified into integral and combined type. Our crank arm has been certified by MAN and classification societies. It can be produced in batches.

Crankshafts

Crankshafts

Crankshafts

Ship shafts