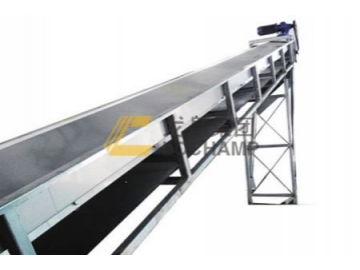

Chip Conveyor (Conveyor using Permanent Magnet for Separating Metal Chips)

Based on our years’ experience, we provide with customers this specialty conveyor geared to separating metal chips. As it is equipped with permanent magnet, this chip conveyor has a strong magnetic force by which metal powders, grains and metal chips(of length< 50mm) or chips in the oil and emulsions could be drawn onto to magnet plate of the chip conveyor. These metal powders, chips and grains will be then conveyed to the designed spot or collection box.

Moreover, all rotation parts of this chip conveyor are well sealed, ensuring the stable, smooth and low-noise operation of the conveyor as well as its long lifespan. Since it handles metal chips with fixed quantity, it will never be overloaded.

Features

1. The maximum absorption amount of each group of magnetic material is fixed. The conveying amount could be adjusted according to the conveying speed and the interval between each two groups of magnets.

2. It could handle chips shorter than 50mm, grains and powders;

3. It could cooperate with other conveying equipment and filtration devices, not so excellent in operation if there are coolant oils.

4. Dimensions of each section and the coolant box are designed according to the types of cutting machines.

Applications

Given its advantages, it has been widely used as a conveying device for CNC machines, combination lathes, machining centers, gear processing machines, automated production lines and the treatment of irons in the dry or wet machining. Therefore, this conveying device has become a choice auxiliary device for the modern machinery.

| Model | B | B1 | H(m) | H1 | H2 L1 | L(m) | α | Chip Discharging Volume (kg/min) | Motor Power (kW ) | Cooling Pump Flow Rate (L/min) |

| 250 | >350 | 0 ~3.00 | 170,204 | Customized | 0.60~10.00 | 0° 30° 45° 60° | 100 | 0.2~0.75 | 25 50 100 200 300 | |

| 300 | >400 | 0 ~5.00 | 150 | 0.2~1.5 | ||||||

| 350 | >450 | 0 ~10.00 | 0.60~30.00 | 200 | 0.4~1.5 | |||||

| 400 | >500 | 250 | ||||||||

| 450 | >550 | 300 | ||||||||

| 500 | >650 | 400 | ||||||||

| 550 | >750 | 500 |