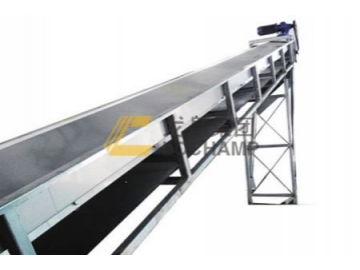

Chip Conveyor (Hinged Belt Type Conveyor for Collecting Metal Chips)

Hinged belt type chip conveyor is a type of chip conveying device designed for collecting metal chips. It could effectively collect metal chips(black chips and non-ferrous metal chips) and convey them to the box.

As it is equipped with and corrosion-and-abrasion resistant parts, overload and current protection devices,this belt type conveyor, made of premium stainless steel plates, is efficient, reliable and quiet in operation. Moreover, it is also equipped with a hinged chain plate with multiple spherical surfaces, free from being stuck with small light chips.

Features

1. Of small size and high efficiency, it is perfect choice for CNC machines, NC machines and other industrial machinery;

2. Designed with chains with different width, is has wider range of applications;

3. It is equipped with premium chains of integral structures and high strength, quite reliable and quiet in operation;

4. The dense salient points design could effective prevent the chips from sticking to the chains, increasing the chip removal capacity of the conveyor;

5. The limitation for torque setting effectively reduce failures caused by misoperation.

Applications of Chip Conveyor

1. This auxiliary equipment has been widely as the chip conveying devices of such industrial production equipment as CNC machines, combined lathes, machining centers, specialty lathes and automated production lines and so on;

2. It could also serve as a small-sized conveying device. Therefore, it has become an indispensable lathe accessory in the modern industrial productions.

| Model | B | B1 | H(m) | H1 | H2 L1 | L(m) | α | Discharging speed (kg/min) | Motor power (kW ) | Cooling Pump Flow Rate (L/min) |

| 250 | >350 | 0 ~2.00 | 100 | Customized | 0.60~5.00 | 0° 30° 45° 60° | 15 | 0.2~0.4 | 25 50 100 200 300 | |

| 300 | >400 | 0 ~3.00 | 0.60~10.00 | 20 | 0.2~0.75 | |||||

| 350 | >450 | 0 ~5.00 | 100, 175, 205 | 0.60~30.00 | 30 | 0.2~1.5 | ||||

| 400 | >500 | 40 | ||||||||

| 450 | >550 | 0 ~10.00 | 175, 205 | 50 | ||||||

| 500 | >650 | 60 | ||||||||

| 550 | >750 | 70 |

Note: A model has no water tank and B has. Customized conveyors are available if required.

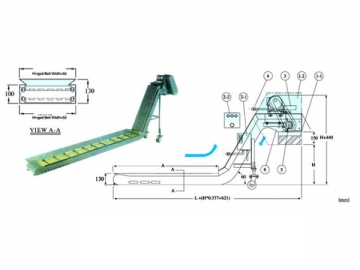

Structure