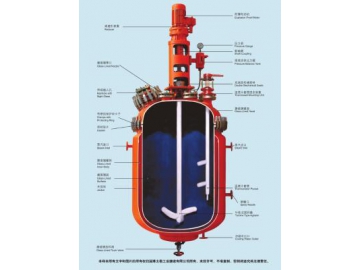

Air Core Reactor

Applications

We provide a variety of air-core reactors which can be used for reactive power compensation, eliminating harmonics, limiting current and so on. The compatible voltage ranges from 0-35KV, and capacity 0-3500Kvar. The reactor we produce is wound parallel with multiple layers into a cylindrical structure. The equipment is separated by a draw bar to form a ventilating air passage, providing a good heat dissipation. Also our reactor is made of thin round wires, which reduces eddy current loss and leakage loss. In terms of insulation, the polyester film at the surface of wires are highly dielectrical. The winding is wrapped tightly with glass fiber impregnated with epoxy insulating glue. The solidifying at high temperature makes it mechanically strong and able to withstand short-circuit currents impact. The coil surface is protected from ozone gases and UV, and is stable under all kinds of bad weathers.

We provide various series of products including series reactors, shunt reactors, filter reactors and current limit reactors.

Specifications| Size | Rated capacitor(kvar) | Reactance rate% | Outline size external diameter D x height H | Install diameter mm | Single phase weight KG |

| 300 | 1 | 580x600 | 430 | 43 | |

| 600 | 1 | 580x560 | 430 | 46 | |

| 900 | 1 | 580x530 | 430 | 50 | |

| 1200 | 1 | 585x490 | 430 | 54 | |

| 1500 | 1 | 680x440 | 530 | 58 | |

| 1800 | 1 | 680x420 | 530 | 60 | |

| 2100 | 1 | 680x600 | 530 | 71 | |

| 2400 | 1 | 680x580 | 530 | 75 | |

| 2700 | 1 | 680x550 | 530 | 78 | |

| 3000 | 1 | 680x550 | 530 | 81 | |

| 3300 | 1 | 680x550 | 530 | 86 | |

| 3600 | 1 | 680x535 | 530 | 88 | |

| 3900 | 1 | 680x530 | 530 | 90 | |

| 4200 | 1 | 680x520 | 530 | 92 | |

| 4500 | 1 | 680x520 | 530 | 96 | |

| 4800 | 1 | 680x520 | 530 | 99 | |

| 5400 | 1 | 680x520 | 530 | 101 | |

| 6000 | 1 | 860x550 | 710 | 113 | |

| 6600 | 1 | 860x540 | 710 | 117 | |

| 7200 | 1 | 860x530 | 710 | 121 |

Execution standard

GB10229-88 "the reactor"

DL462-92 "high voltage capacitor in series reactor order technical conditions"

JB5346-1998 "series reactor"

IEC289-88 "the reactor"

JISC4801-1997 "series reactor used in high pressure and special high voltage parallel capacitor,

Environment requirements

1. Working conditions: indoor or outdoor.

2. Temperature: -40 ℃ to 45 ℃.

3. Altitude ≤ 1000m

4. No harmful gases, steam and conductive or explosive dust at the installation site.

5. Relative humidity ≤ 90%

6. Maximum wind speed: 35m / s

7. Earthquake intensity ≤ 8 degrees

8. Anti-fouling capacity ≥ 25mm / kv

Features

1. In normal using, the voltage on a traditional reactor is always high, thus more reactive power is consumed. For example, a 14% reactor works at 35V in normal status, and 2.86kvar reactive power is consumed on it.

Real voltage on the capacitor = 380*(1+14%) =433V, and the relative voltage on the capacitor=27.2A*1.732*433=20.4Kvar. Actual compensation to the system reactive power=20.4-2.86=17.54kvar, and the capacitor utilization is only 58.5%.

However, when our air core reactor is applied, the voltage of the same capacitor decreases to 2.2V, and only 0.215Kvar reactive power is consumed. The actual terminal voltage of the capacitor = 383V, the actual reactive power of the capacitor = 33A * 1.732 * 383 = 21.89Kvar. With actual compensation to the system reactive power = 21.67kvar, the capacitor utilization can reach 72.2%

2. Our air core reactor can be used in systems with high voltage. With a small magnetic density of 0.18T, the iron core make no noise even under the highest harmonics voltage, and the temperature rise is quite low.

3. Appling an air core reactor can compensate for system reactive power harmonics, and reduce system voltage distortion.