High Voltage Motor Stating Reactor

Applications

The QKSC high voltage motor stating reactor can reduce the voltage when starting up an AC induction motor. This product is designed to match the starting process of high-voltage asynchronous motors, and us compatible with motors of 220V to 14000KW.

When starting an AC induction motor at the rated voltage, the starting current always goes up to 5-7 times of the rated current. In order to reduce the starting current to avoid affecting the whole power grid, induction motors are usually started with lower voltages. An AC motor take a short time to startup, (usually a few seconds to two minutes), and by simply applying a reactor the voltage can be reduced.

Specifications| Starting reactor model | Starting capacitor Kv | Starting current | Reactance(Ω) | outline size L x w x H mm | Be started reactance machine | |

| model | power(KW) | |||||

| 395 | 123 | 8.667 | 865x300x700 | Y355-4 | 220 | |

| 445 | 139 | 7.669 | 895x340x730 | Y355-4 | 250 | |

| 495 | 154 | 6.992 | 910x345x740 | Y355-4 | 280 | |

| 555 | 173 | 6.162 | 925x350x760 | Y355-4 | 315 | |

| 620 | 194 | 5.496 | 940x355x785 | Y400-4 | 355 | |

| 700 | 219 | 4.868 | 955x360x800 | Y400-4 | 400 | |

| 785 | 246 | 4.333 | 975x360x820 | Y400-4 | 450 | |

| 855 | 267 | 3.993 | 1015x385x840 | Y400-4 | 500 | |

| 965 | 301 | 3.542 | 1030x385x880 | Y400-4 | 560 | |

| 1080 | 338 | 3.154 | 1090x390x920 | Y450-4 | 630 | |

| 1215 | 380 | 2.805 | 1105x390x920 | Y450-4 | 710 | |

| 1365 | 427 | 2.496 | 1120x410x970 | Y450-4 | 800 | |

| 1540 | 481 | 2.216 | 1135x410x1015 | Y450-4 | 900 | |

| 1845 | 499 | 2.469 | 1150x420x1060 | Y500-4 | 1000 | |

| 2040 | 552 | 2.232 | 1170x430x1095 | Y500-4 | 1120 | |

| 2275 | 615 | 2.003 | 1125x440x1120 | Y500-4 | 1250 | |

| 2545 | 688 | 1.791 | 1250x445x1145 | Y500-4 | 1400 | |

Note: The table above shows size parameters of our conventional products. Customization service is also available.

When using customization services, the user should provide following parameters:

1. Rated voltage.

2. Rated current.

3. Rated reactance.

4. Startup running time and continuous startup times

5. Starting and cooling cycle.

6. The conditions of use (outdoor or indoor).

7. Other performance data according to the requirements.

Environment requirements

1. Altitudes lower than 1000 meters.

2. Operating environment temperature -25℃ to 45℃.

3. No harmful gases, steam and conductive or explosive dust at the installation site

4. When the working time reaches 2 minutes (once or accumulated), the device should be cooled for 6 hours before it can start again.

Performance parameters

1. Our dry-start reactors have smaller size compared with traditional oil reactors. They are light weight, have simple structure and are easy to install.

2. High temperature level (F).

3. The loss of dry iron core starting reactors is lower than that of oil reactors.

4. Noise level under 50dB

Features

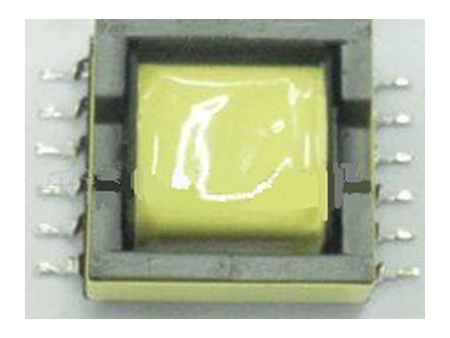

1. Our high voltage motor stating reactors are made from cold rolled silicon steel of good quality. The core is separated evenly by air vents. Epoxy coat are applied in the gaps with special glue to ensure the air vents unaffected when the device is working.

2. High-quality silicon steel glue is used at the ends of the iron core, which greatly reduces running noise, and is corrosion-proof.

3. The main insulation part of the coil is made of glass fiber epoxy resin. The drying and vacuum immersing in insulating paint process adds to the coil’s good insulation properties and high mechanical strength. It can withstand the current impact when starting motors and extreme temperatures without breaking.