Laser die-cut for Label Roll FC300-B-A

| Model | FC300-B-A |

| Laser power(W) | 20-50(Fiber)/3-5(UV)/30(CO2) |

| Working area (mm) | Roll width: 10-300 |

| Working speed(mm/s) | 0-7000 |

| Weight (Kg) | 300 |

| Overall dimension(mm) | 1450x770x1600 |

| Power supply | AC220V/10A±5% |

| Working environment | Temp.: 10 ~30 ℃, Humidity: 5 ~8 5 %, no condense water, no dust or less dust. |

| Total Power (kw) | 2 |

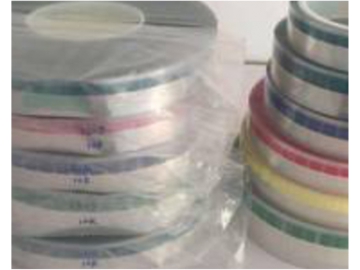

Laser Processing Examples:

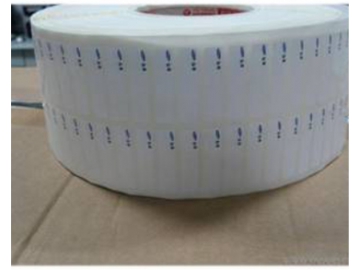

Label marking

Label marking Steel strip marking

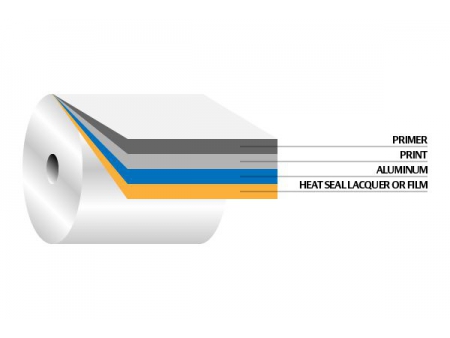

Steel strip marking Aluminum foil marking

Aluminum foil marking Film marking

Film marking

Product Feature

1.Roll to roll automatic loading and unloading; automatic alarm for full or short of material; adjustable marking speed; long time running process without accumulated errors; automatically processing products.

2.Vision positioning process and sensor positioning process are optional without affecting the efficiency and marking accuracy can be improved to ±0.1mm.

3.Imported core components are optional with excellent performance, stable quality and long service life.

4.The laser die-cut adopts an integrated design of machine hardware, control system and working platform to achieve small footprint and easy operation.

5.Self-developed marking control software has a powerful and user-friendly interface, simple and fast operations, which make it easy to learn and use.

6.High compatibility: Support DXF, PLT vector and image format; Support dot matrix fonts and TTF fonts as well as self-developed fonts; Support two-dimensional code, pictures, characters and other content marking; Support a variety of galvo head correction methods; Able to meet customer needs of different grades.

7.Diverse laser sources are optional: UV, fiber or CO2 laser source, suitable for processing metal, PE, cloth and a wide range of materials.