Pouch Liquid Packaging Machine

Request a Quote

Pouch Machines

Vertical Form Fill Seal Machines with Multihead Weigher for Liquids and Viscous Products

- Dosing System

- Liquid Pump Filler

- Bags Per Hour

- 300-3600

- Bag Volume

- 2000 to 14000ml

- Bag Size (Length × Width)

- 80-500mm × 60-350mm

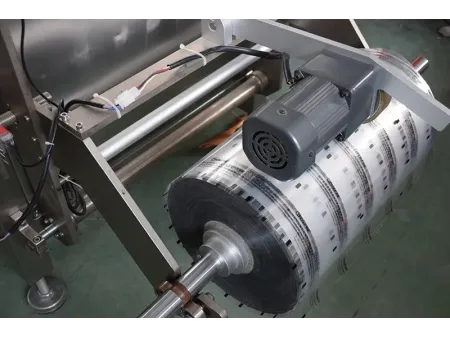

Film feeding system

Liquid filling system

Electrical cabinet

Control panel and switch

Applications

Ideal for packaging standard, viscous, and high-viscosity liquid products, such as peanut butter, ketchup, shampoo, body wash, face cream, sauces, jams, condiments, milk, juice, and mayonnaise.

Configurations

- VFFS Packaging Machine

- Low Volume Liquid Pump (50-500ml)

- Medium Volume Liquid Pump (100-1000ml)

- High Volume Liquid Pump (500-5000ml)

- Liquid Pump Filler

Features

- Versatile Compatibility: Integrates with liquid or paste pumps for fully automated packaging of liquids and pastes with varying viscosities.

- Automatic Supply Control: Features linked system control for efficient feeding, ensuring no packaging occurs without material, reducing waste.

- Durable and Hygienic: Liquid pump components in contact with materials are made from 316 stainless steel, providing rust resistance and long-term reliability.

Designed for standard, viscous, and high-viscosity liquid materials, this fully automated packaging system offers smooth control for your production line. It features integrated supply management with an intelligent no-material, no-packaging detection system, ensuring efficiency and minimal waste.

Kinds of Pouches: 3-side, four edge-sealing bag, self-reliance bag, handbag, spout bags, zipper bag, compound bag, etc

| Model | |

| Film Width | Max.420mm |

| Bag Length | 80-300mm |

| Bag Width | 60-200mm |

| Film Roll Diameter | Max.320mm |

| Packaging Speed | 300-3600bags/hour |

| Bag Volume | 2000ml |

| Film Thickness | 0.04-0.12mm |

| Power Supply | 220V, 50/60Hz, 3kW |

| Machine Dimensions (L×W×H) | 1217×1015×1343mm |

| Optional | Air Filling Device, Gusseting Device |

| Film Material | BOPP/CPP, BOPP/VMCPP, BOPP/PE, PET/VMPET/PE, PET/AL/PE, PET/PET etc. |

| Model | |

| Film Width | Max.520mm |

| Bag Length | 80-350mm |

| Bag Width | 100-250mm |

| Film Roll Diameter | Max.320mm |

| Packaging Speed | 300-3600bags/hour |

| Bag Volume | 4000ml |

| Film Thickness | 0.04-0.12mm |

| Power Supply | 220V, 50/60Hz, 3kW |

| Machine Dimensions (L×W×H) | 1488×1080×1490mm |

| Optional | Air Filling Device, Gusseting Device |

| Film Material | BOPP/CPP, BOPP/VMCPP, BOPP/PE, PET/VMPET/PE, PET/AL/PE, PET/PET etc. |

| Model | |

| Film Width | 150-620mm |

| Bag Length | 100-450mm |

| Bag Width | 65-300mm |

| Film Roll Diameter | Max.320mm |

| Packaging Speed | 300-2700bags/hour |

| Bag Volume | 8000ml |

| Film Thickness | 0.04-0.12mm |

| Power Supply | 220V, 50/60Hz, 3.2kW |

| Machine Dimensions (L×W×H) | 1488×1180×1550mm |

| Optional | Air Filling Device, Gusseting Device |

| Film Material | BOPP/CPP, BOPP/VMCPP, BOPP/PE, PET/VMPET/PE, PET/AL/PE, PET/PET etc. |

| Model | |

| Film Width | 150-720mm |

| Bag Length | 100-500mm |

| Bag Width | 65-350mm |

| Film Roll Diameter | Max.320mm |

| Packaging Speed | 300-2400bags/hour |

| Bag Volume | 14000ml |

| Film Thickness | 0.04-0.12mm |

| Power Supply | 220V, 50/60Hz, 3.5kW |

| Machine Dimensions (L×W×H) | 1780×1350×2050mm |

| Optional | Air Filling Device, Gusseting Device |

| Film Material | BOPP/CPP, BOPP/VMCPP, BOPP/PE, PET/VMPET/PE, PET/AL/PE, PET/PET etc. |