PAUT/AUT Bottom Discharge Scraper Centrifuges with Top Mounted Motor

Introduction

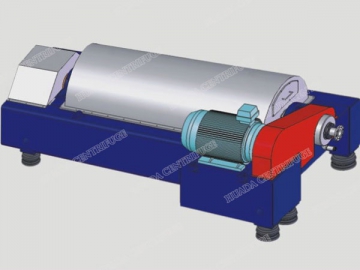

The PAUT/AUT bottom discharge scraper centrifuges with top mounted motor are the batch-type centrifuges. This automatic filter centrifuge involves the utilization of hydraulic system and electronic control system, and can be switch to manual operation upon request. Top-mounted motor eliminates the annoying problem of friction dust caused by conveyor belt.

Main Features of PAUT/AUT Scraper Centrifuge

1. Top-mounted motor makes rotary center of the drive and basket coincide with the center of this suspended basket centrifuge, thus delivering stable operation.

2. Our motor-driven centrifuge is fitted with liquid damping isolator and requires no foundation for installation, resulting in minimized workload of operation and maintenance.

3. Machine housing and base are connected rigidly for simple and compact structure.

4. Independent bearing seat comes with large support capacity on the basis of low center of gravity of basket.

5. No utilization of belt brings no friction dust.

6. Fully automatic operation control ensures safe and dependable performance.

7. Optional nitrogen protection system is available for explosion-proof application.

8. Options of base plate and three point suspension are available.

Applications of PAUT/AUT Scraper Centrifuge

Our industrial filtration equipment has been proved to be ideal for slurries separation featuring large viscosity, strong hydrophilicity and hard-to-separate, as well as particles containing medium-sized or fibroid material. It also finds applications in separation of some crystalloid solid-state materials (granular, fibroid, flaky, etc.) in loosen state or with slight viscosity.

Thanks to exceptional adaptability to materials, our scraper centrifuge is the tool of choice to separate slurries containing solid phase ≥0.05mm and with great thermal sensitivity. Based on hydraulic narrow scraper and low-speed enclosed discharging, this centrifuge features outstanding cake discharge capability and minimized damage on crystals, which are enjoyed by industries of chemical, pharmacy, food, environment protection and light industry, etc.

Optional Configuration of PAUT/AUT Scraper Centrifuge

1. Feeding method: side feed via single tube or multiple tubes

2. Scraper discharge: pneumatic or hydraulic

3. Motor drive: Common motor, explosion-proof motor

4. Protection: nitrogen protection system, explosion proof, vibration protection, electric-mechanical interlocking, overload protection

5. Surface treatment: Mirror finishing, matt finishing, and dulling

6. Discharge hopper: custom diameter and height

7. Residual cake treatment: recoil or air-assist scraper

8. Program control: PLC, cake level detector

9. Nitrogen protection system: automatic nitrogen supplier, hydraulic sealing device and gas-liquid separator

10. Coating treatment: HALAR lining, PE lining

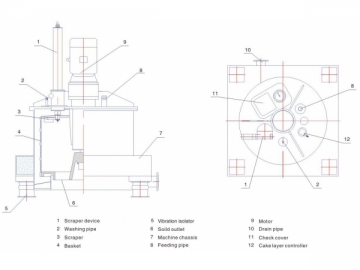

Structure of PAUT/AUT Scraper Centrifuge

Parameter

Technical Parameter of PAUT/AUT Scraper Centrifuge

| Item | Model | ||||

| Basket Dia. (mm) | 1250 | 1000 | 1250 | 1600 | 1600 |

| Basket Volume (L) | 281 | 175 | 380 | 775 | 775 |

| Max. Load (kg) | 380 | 235 | 380 | 1050 | 1050 |

| Max. Speed (rpm) | 970 | 1050/1300 | 970 | 850 | 850 |

| Centrifugal Force | 658 | 620/950 | 658 | 647 | 647 |

| Motor Power (kW) | 22 | 11/15 | 22 | 37 | 37 |

| Dimension (L×W×H) (mm) | 2100×2000×2235 2150×2000×2150 | 2100×2000×2600 2150×2100×2800 | 2100×2000×2600 2150×2100×2800 | 2600×2350×2700 2650×2600×2600 | 2700×2350×2900 2650×2550×3500 |

| Weight (kg) | 4200/3800 | 4800/4300 | 5000/4500 | 8500/8000 | 10000/8800 |

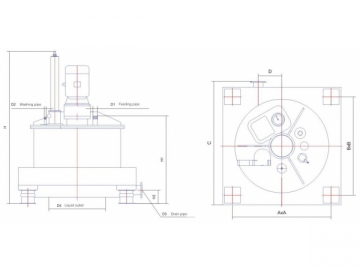

Installation Dimension

| Model | A×A | B×B | C | D | H | H0 | H1 | H2 | D1 | D2 | D3 | D4 |

| 2000×2000 | 1670×1670 | 2100 | 400 | 2235 | 1390 | 506 | 395 | 50 | 25 | 150 | 950 | |

| 2000×2000 | 1670×1670 | 2100 | 400 | 2600 | 1495 | 610 | 226 | 65 | 25 | 150 | 950 | |

| 2000×2000 | 1670×1670 | 2100 | 400 | 2600 | 1495 | 624 | 232 | 80 | 25 | 150 | 1040 | |

| 2350×2600 | 1900×2150 | 2700 | 400 | 27200 | 1450 | 620 | 230 | 80 | 25 | 150 | 1050 | |

| 2350×2600 | 1900×2150 | 2100 | 400 | 2600 | 1640 | 670 | 230 | 80 | 25 | 150 | 1200 |