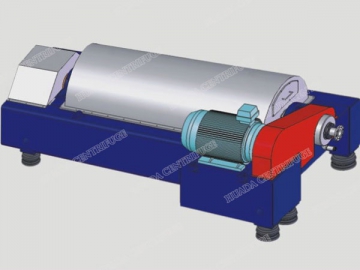

SGZ Three-column Automatic Bottom Discharge Scraper Centrifuges

The SGZ three-column automatic bottom discharge scraper centrifuges are mainly applicable for washing of slurries containing solid phase as well as solid-liquid separation. The suitable solid phase size is 0.05-1mm, and filtration cake density is limited from 1.0 to 1.5. The solid content in slurry is ranged from 15% to 50%. Moreover, slurries should be uniform and continuous, and have exceptional mobility in pipeline.

Applications of SGZ Scraper Centrifuge

Our chemical separation equipment is the proven solution for treatment of plaster, ammonium sulfate, mirabilite, ferric sulfate, copper sulfate, nickel sulfate, potassium chloride, acetic acid, borax, soda, rubber additive, dyestuff, starch, sugar refining, vitamin, antibiotics, herbicide, vermifuge, copper, zinc, aluminum, anhydrite, metal refining, pure water sludge and sewage sludge.

This pharmaceutical separation equipment also is well-suited for all kinds of medicines.

Main Features of SGZ Scraper Centrifuge

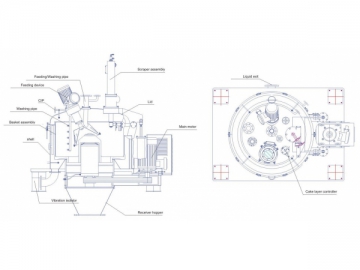

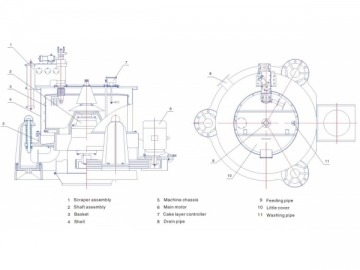

1. Three point suspended structure is economically and practically fitted with spring vibration absorbing system.

2. Variable frequency drive for speed adjustment comes with stable start-up and adjustable centrifugal force.

3. Hydraulic scraper discharge is controlled by PLC system and fully automatic workflow meets your expectation on cake layer control, feeding, filtration, washing, dewatering and discharge.

4. Dynamic braking makes our wastewater treatment equipment to be free from friction dust.

5. Thanks to middle feeding and semi-opening cover, our automatic filtration centrifuge is capable of catering to general requirements in chemical production.

6. Protection: rotation speed detection, over-vibration protection, motor overload and overheat protection, scraper movement protection, limit protection of lifting equipment, interlocking protection of scraper and basket, etc.

7. Our three-column centrifuge allows for various configurations to meets demanding needs in industries of chemical and pharmaceutical.

Note on Configuration of SGZ Scraper Centrifuge

During order making, special attention should paid on specific requirements of variable frequency drive, braking method, material, feeding method, explosion-proof, corrosion resistance, surface finish, electrical component and control system, etc.

Note

Traditional dual clutch drive is available, but not recommended.

Technical Parameter of SGZ Scraper Centrifuge

| Item | Model | ||

| Basket Dia. (mm) | 800 | 1000 | 1250 |

| Basket Volume (L) | 100 | 140 | 280 |

| Max. Load (kg) | 135 | 210 | 420 |

| Max. Speed (rpm) | 1200 | 1000 | 900 |

| Centrifugal Force | 645 | 560 | 565 |

| Motor Power (kW) | 7.5 | 11 | 18.5 |

| Dimension (L×W×H) (mm) | 1900×215100×1730 | 2150×1750×2200 | 2500×2000×2500 |

| Weight (kg) | 2300 | 3500 | 4500 |