MIG Welding Machine, Wire Feed MOSFET Welder

Main Parameters

Applicable Welding Wire Diameter: 0.8/0.9/1.0/1.2mm (MIG mode), 1.6-5mm (MMA mode)

Applicable Power Supply: Three Phase

Rated Input Voltage: 220V/380V

Rated Input Power: 6.0kW-11.3kW

Rated Input Current: 10A-34A

Open Circuit Voltage: 60V/61V

Protection Class: IP23

Insulation Class: H

Cooling System: Forced air cooling

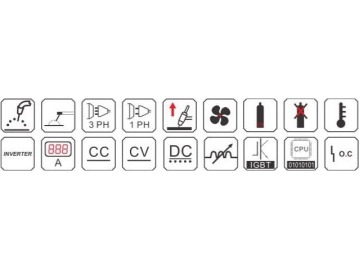

Our MIG250/300GM series MIG welding machine is designed with a built-in welding wire reel and wire feed unit, contributing to easy operation. It integrates MMA welding, MIG welding and TIG welding together, resulting in a high performance cost ratio and accommodating various welding needs from different customers. The welding machine can be applied for welding carbon steel, ordinary low alloy steel and stainless steel.

Features

- In MMA welding mode, a lift TIG contact arc start method is applied. In MMA welding mode, LIFT TIG contact type arc striking method is applied. The arc striking is achieved by direct contact between the tungsten electrode and the workpiece resulting in short circuit. As a result, the arc will be easily struck and the arc obtained is quite soft.

- The built-in thrust regulation system is able to prevent arc extinction during the welding process and make the welding current larger as the electrode moves closer towards the workpiece, thereby eliminating welding spatter.

- When the working voltage or current is too high or the welding machine is over heated, the overheat protection, overcurrent protection and low voltage protection features will be enabled automatically, further ensuring operation safety.

- The VRD (voltage reduction device) feature will be applied in MMA welding mode, resulting in low open circuit voltage and further achieving electrify shock protection. In this way, the safety of the operator will be sufficiently guaranteed.

- Operator is enabled to select 2T or 4T mode as needed. They are suitable for spot welding, short seam welding, and long seam welding.

- The welding machine is compact and lightweight. With casters installed at the chassis, it is very easy to move the welder around.

| Model | MIG250GM | MIG300GM | |||||||

| Wire Diameter | 0.8/0.9/1.0mm | 1.6-4.0mm | 0.8/1.0/1.2mm | 1.6-5.0mm | 0.8/1.0/1.2mm | 1.6-5.0mm | |||

| Rated Input Voltage | 3P 220V | 3P 380V | 3P 380V | ||||||

| Frequency | 50/60Hz | 50/60Hz | 50/60Hz | ||||||

| Welding Mode | MIG | MMA | TIG | MIG | MMA | TIG | MIG | MMA | TIG |

| Rated Input Power | 8.3KW | 9.4KW | 6.3KW | 7.8KW | 8.8KW | 6.0KW | 10.2KW | 11.3KW | 7.8KW |

| Rated Input Current | 30.0A | 34.0A | 22.5A | 13A | 15A | 10A | 17A | 18.8A | 13A |

| Rated Output Current Range | 50-250A | 50-250A | 15-250A | 50-250A | 50-250A | 15-250A | 50-300A | 50-300A | 15-300A |

| Duty Cycle (40°C 10min) | 60%250A, 100%194A | 60%250A, 100%194A | 40%300A, 100%232A | ||||||

| Open Circuit Voltage | 61V | 60V | 60V | ||||||

| Efficiency | ≥80% | ≥85% | ≥85% | ||||||

| Power Factor | 0.73 | 0.93 | 0.93 | ||||||

| Protection Class | Ip23 | Ip23 | Ip23 | ||||||

| Insulation Class | H | H | H | ||||||

| Cooling System | AF | AF | AF | ||||||

| N.W | 60.0KG | 60.0KG | 60.0KG | ||||||

| G.W. | 64.0KG | 64.0KG | 64.0KG | ||||||

| Packing Dimesnion | 960×415×815mm | 960×415×815mm | 960×415×815mm | ||||||

Customization

The appearance, welding current, product manuals and package of our MIG welding machine can be customized according to customer requirements.

- Multi-function Welding Torch

- TIG Welding Torch

- Earth Clamp

- Mask

- Hammer Brush

- PU Tubing

- Wrench