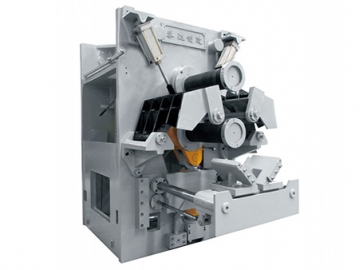

UBM Cold Roll Forming Machine, CS-914-610

High Construction Speed

With the use of an ABM vertical type cold roll forming machine, a 1,000 square meter metal structure can be built in as little as 24 hours. Using the high fabrication speed and panel seaming, a crew of 10 to 12 people can fabricate and erect nearly 100 arched panels in a single day.

Low Cost

With the high speed, the cost of construction of a UBM building is less than that of conventional and prefabricated buildings.

On Site Manufacturing

The UBM mobile factory is taken directly to the construction site, and the building is completely fabricated on site. There are no extra costs for shipping the building components from the factory to the site.

Mobility and Access to Remote Areas

The trailer mounted ABM factory is easily towed by ordinary vehicles to remote locations and can be put into use immediately upon arrival.

No Structural Clamps, Beams or Trusses Required

The UBM arches are designed to be completely self-supported, and do not require support structures like those in standard steel frame buildings.

Manpower Savings

A crew of approximately 10 to 15 trained people can erect a 1,000 square meter building in a single day. Users can build their ABM buildings in either steel or aluminum, and both materials are available pre-painted in a range of colors. We also stock most of our coils and immediately ship them with the unit to the construction site.