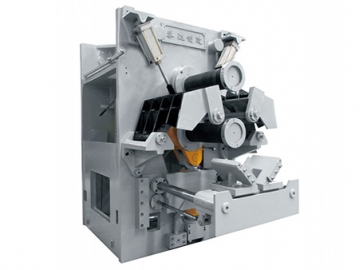

UBM Cold Roll Forming Machine, CS-1000-550

The CS-1000-550 ABM vertical cold roll forming machine is a self-contained, trailer mounted mobile factory designed to produce steel buildings on site from steel coil stock. It is towed to the construction site, where it is set up by a small crew adjacent to the building location. One set works as a complete production line, carrying out forming, curving and cutting.

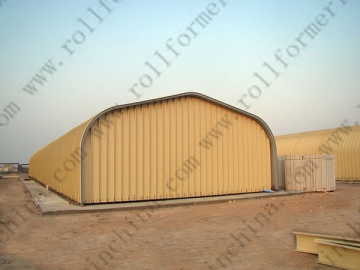

The curved panels are available in a traditional gable shape (straight side walls and a pitched roof), a rounded, double radius shape (straight side walls and a broadly curved roof section) or in the form of a circle arc with a fixed radius.

The finished panels are carried to an assembly area where they are connected together in groups of three using a patented electrically powered seaming machine. The seamed connections are waterproof and require no bolts or other fasteners. After the three panels are assembled, they are lifted using a crane and furnished by the builder. The panel section is then placed into a foundation that has been prepared in advance. This process is repeated until the desired building length is achieved. There is no limit to the length of the building.

The interior of the building is easily furnished just as any other building is with insulation, electricity, plumbing, heating and cooling, and partitions.