PLD Pull Action Filter Centrifuge with Scraper Bottom Discharge

Introduction

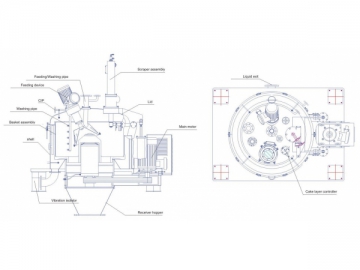

The PLD pull action filter centrifuge with scraper bottom discharge are developed on our own and have achieved invention patent. This solid-liquid separation centrifuge remains the main functions of LGZ series such as separation and scraper discharge. Our pharmaceutical centrifuge features pull action filter to offer more than 99% cake removal rate.

This food centrifuge bypasses batch cross among different products and the negative impacts on filtration efficiency caused by residual cake. Based on these advantages, our chemical centrifuge has been extensively applied to solid-liquid separations of crystallized materials for industries of pharmacy, food and chemical, etc.

Main Features of PLD Pull Action Filter Centrifuge

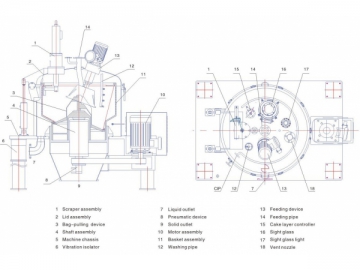

In addition to all features of LGZ series bottom discharge scraper centrifuge, our PLD pull action filter centrifuges also features following advantages

1. Residual cake remove is conducted by pulling the filter cloth using pneumatic device, thus offering complete discharge.

2. Removable liquid block plate is available in basket to provide reliable self-locking and easy replacement of filter cloth.

3. Built-in cylinder comes with more compacted structure.

4. Self-cooling rotary joint delivers more reliable performance.

5. Fully enclosed discharge hopper isolates products from driving components on this explosion-proof separation equipment.

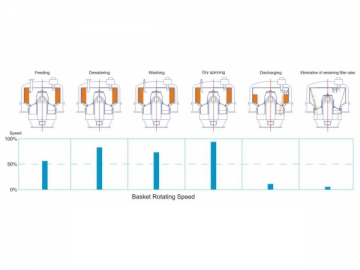

Workflow of PLD Pull Action Filter Centrifuge

Optional Configuration of PLD Scraper Bottom Discharge Pull Action Filter Centrifuge

1. Cover: Large cover, full cover, flat cover

2. Feeding method: inclined feed tray, side feed tube, cake level detector

3. Scraper discharge: pneumatic, hydraulic, liquid-phase skimming disc

4. Motor drive: common motor, variable frequency drive motor, explosion-proof motor

5. Protection: nitrogen protection system, explosion proof, vibration protection, temperature protection, electric-mechanical interlocking, rotation monitoring and overload protection

6. CIP system: cleaning ball and spray pipe

7. Nitrogen protection system: automatic nitrogen supplier, hydraulic sealing device and gas-liquid separator

Parameter

Technical Parameter of PLD Pull Action Filter Centrifuge with Scraper Bottom Discharge

| Item | Model | |||

| Basket Dia. (mm) | 800 | 1000 | 1250 | 1600 |

| Basket Volume (L) | 100 | 175 | 380 | 775 |

| Max. Load (kg) | 125 | 235 | 380 | 1050 |

| Max. Speed (rpm) | 1200/1500 | 1050/1300 | 970 | 850 |

| Centrifugal Force | 1008 | 620/950 | 658 | 647 |

| Motor Power (kW) | 7.5/11 | 11/15 | 22 | 37 |

| Dimension (L×W×H) (mm) | 1900×1250×2300 | 2100×1500×2250 | 2450×1800×2047 | 3000×2200×2700 |

| Weight (kg) | 5500 | 8500 | 13000 | 20000 |

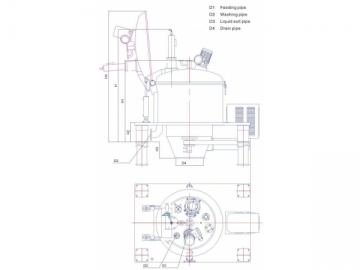

External Dimensions and Piping of PLD Pull Action Filter Centrifuge

| Model | A | A1 | B | B1 | C | D | E | H | H0 | H1 | H2 | H3 | D1 | D2 | D3 | D4 |

| 1870 | 1750 | 1250 | 1200 | 1450 | 900 | 720 | 2100 | 2365 | 1650 | 290 | 250 | 40 | 25 | 80 | 500 | |

| 2230 | 2040 | 1500 | 1450 | 1760 | 1170 | 910 | 2300 | 2430 | 1480 | 370 | 490 | 50 | 25 | 100 | 500 | |

| 2700 | 2505 | 1700 | 1700 | 2200 | 1390 | 1183 | 2450 | 2860 | 1765 | 420 | 352 | 65 | 25 | 125 | 600 | |

| 3000 | 2800 | 2155 | 2100 | 2100 | 1600 | 1110 | 2720 | 3625 | 2030 | 487 | 705 | 80 | 25 | 150 | 800 |