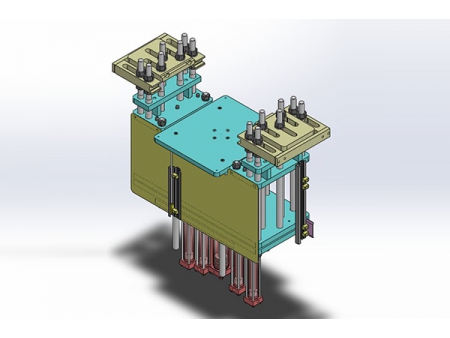

2RT Rubber Vulcanizing Press

Request a Quote

Applications

The 2rt rubber vulcanizing press is designed and manufactured to manufacture a number of different rubber and silicone based products. These products include O-rings, sealing elements, rubber strips, EVA foam slippers, rubber floor tiles, etc.

Functions

This rubber vulcanizing press has functions of automatic lifting, stable mold clamping, automatic gas discharging, automatic pressure compensation, vulcanization timer, automatic constant temperature, timer alarm, automatic mold opening, automatic push-pull and automatic mold ejection.

Parameters

| Model | ||||||

| Nominal clamping force (MN) | 0.25 | 0.50 | 1.00 | 1.60 | 2.5 | 3.15 |

| Heating plate spacing (mm) | 300 | 300 | 300 | 300 | 300 | 300 |

| Heating plate pressure (MPa) | 2.04 | 3.13 | 2.78 | 2.51 | 3.09 | 2.19 |

| Piston stroke (mm) | 250 | 250 | 250/500 | 500 | 400 | 300 |

| Heating method | Electric, gas | Electric, gas | Electric, gas | Electric, gas | Electric, gas | Electric, gas |

| motor power (kW) | 2.2 | 2.2 | 2.2 | 3 | 4 | 4 |

| Dimension (L×W×H) (mm) | 1200×580×1200 | 1400×500×1400 | 1880×820×1680×2150 | 1730×930×2460 | 2345×960×1385 | 2800×1300×2300 |

| Total weight (kg) | 1200 | 1500 | 2500/3100 | 7500 | 6500 | 8500 |

| Structure type | Column type | Column type | Column type | Frame type/ Column type | Frame type / Column type | Frame type / Column type |

Product description

- Easy assembly. The wires between the main engine, electronic control cabinet and hydraulic pressure station are all connected before delivery. Users only need to connect the wire between the workshop and electronic control cabinet and fill the hydraulic pressure station with hydraulic oil, the machine is then ready to operate.

- Custom service. The hot plate dimension, layers, pressures and other parameters of the vulcanizing machine can be customized to meet client demands.

- This series of vulcanizing machine can be equipped with PLC automatic control system for automatic exhaust operation. The exhaust period, interval and times can all be freely adjusted. The machine also has the function of automatic pressure filling to compensate the decrease of the pressure during vulcanization.

Our advantages

- 2rt rubber vulcanizing press is one of the earliest plate vulcanizing machines that Qingdao Shun Cheong Rubber Machinery Manufacturing Co., Ltd. ever designed and brought to market. The current frame plate and C plate nonstandard vulcanizing presses are all designed and manufactured based on the original design of the 2rt rubber vulcanizing press.

- The plate vulcanizing presses with capacities below 100 tons manufactured in our company, if not specially requested by clients, are all column plate types.

- We sell XLB-350×350, XLB-400×400 and XLB-600×600 vulcanizing press models. Over 40 pieces of these three types of vulcanizing machines are produced monthly. Over 30% are sold internationally every year.

What’s the best way to select the right vulcanizing press model?

What’s the best way to select the right vulcanizing press model?

Since most of our vulcanizing presses are customized, the selection of the right vulcanizing machine starts with the dimensions of your product or mold, which determine the heating plate size. We also look at the properties of the rubber and the application to calculate the total pressing force required. Depending on your production needs, we offer a variety of structural designs to suit different production requirements. Our vulcanizing presses options include frame plate and C plate presses, as well as models with sliding platforms or downstroke mechanisms, so you can select the setup that best matches your process and handling needs. If your products have complex shapes or require easier demolding, you can select from different mold-opening systems such as 2RT, 3RT, or 4RT vulcanizing presses to improve efficiency and handling.

How many vulcanizing presses do you produce each year?

How many vulcanizing presses do you produce each year?

Our production covers a broad range of models, with vulcanizing press capacities starting at 10 tons and going all the way up to 20,000 tons. On average, we ship about 15 presses every month. These rubber vulcanizing machines are used across virtually every area of the rubber industry, tires, conveyor belts, rubber sheets, seals, and many other applications.

Can you supply the rubber processing equipment needed before the vulcanizing process?

Can you supply the rubber processing equipment needed before the vulcanizing process?

Of course. We are capable of manufacturing complete rubber processing lines that cover all the upstream steps, including mixing, extrusion, and calendering. Backed by more than two decades in the rubber processing industry, our team can design and deliver a full turnkey solution, so you have everything in place to start production smoothly.