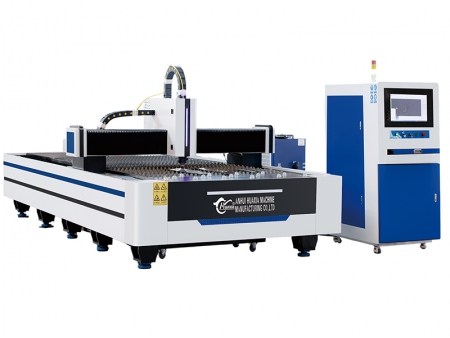

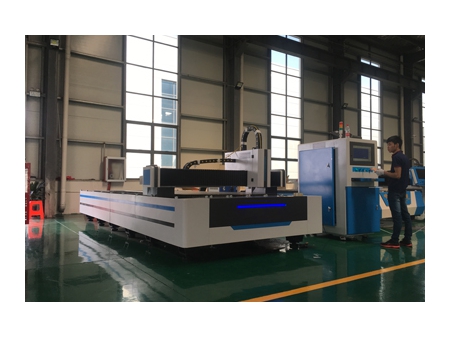

CNC Laser System Metal Cutting Machine

Request a Quote

The laser cutting tube and sheet machine can shear sheets made from various materials, including carbon steel, stainless steel, aluminum alloy and copper. These metals and sheets can all be in various thicknesses.

-

Cuuting Accuracy (mm)

±0.03

-

Max Positioning Speed (mm)

100

-

Max Acceleration (G)

1.5

-

Max Load of Worktable (kg)

250

Technical Parameters

| Model | ||

| Cutting Thickness MS (mm) | 6 | 8 |

| Cutting Thickness SS (mm) | 3 | 4 |

| Cuuting Accuracy (mm) | ±0.03 | ±0.03 |

| Max Positioning Speed (mm) | 100 | 100 |

| Max Acceleration (G) | 1.5 | 1.5 |

| X Axis Track (mm) | 3050 | 3050 |

| Y Axis Track (mm) | 1550 | 1550 |

| Z Axis Track (mm) | 120 | 120 |

| Laser Power (W) | 500 | 750 |

| Max Load of Worktable (KG) | 250 | 250 |

| Machine Weight (KG) | 4500 | 4500 |

| Noise (db) | ˂75 | ˂75 |

| Diemension (mm) | 4500x3100x2200 |

Features

Structure

- X Axis Bilateral Synchronous Drive

- Numerical Control System and Drive

- Laser Cutting Head