Magnesium Oxide (High Purity Powder)

1. General Description

Chinese name: High Purity Magnesium Oxide

English name: magnesium oxide high-purity grade

Other name(s): maglite; magnesium monoxide

Molecular formula: MgO

Molecular weight (MW): 40.30

CAS No.: 1309-48-4

EINECS No.: 215-171-9

High purity magnesium oxide is in the form of white powders, odorless, tasteless, non-toxic, insoluble in water or ethanol, and slightly soluble in ethylene glycol. Its melting point is 2852 ℃ and the boiling point is 3600 ℃. The magnesium oxide is excellent in fire resistance and electrical insulation. Ignition at temperature above 1000 ℃ can turn it into crystal, and when temperature rises above 1500 ℃, the crystal becomes dead burned magnesium oxide (also known as magnesite or periclase) or sintered magnesia.

When exposed to air, the magnesium oxide is prone to absorb moisture and carbon dioxide and so become basic magnesium carbonate. The MgO is soluble in acid and ammonium salt, insoluble in ethanol, hardly soluble in water, and the solution is alkaline. Its slow reaction with water produces magnesium hydroxide. It shows strong refraction within visible and near UV light range.

2. Our Advantages

Our high purity magnesium oxide is made from the calcination of magnesium carbonate, which is produced by chemical synthesis of brine and soda ash at certain concentration and temperature. The advantages of our products include: high purity, high whiteness, uniform particle size, and controllable bulk density and specific surface area.

| Appearance | white powder |

| Assay | ≥98.0 % |

| Surface moisture | ≤0.5 % |

| CaO | ≤0.5 % |

| Hydrochloric acid insoluble | ≤0.05 % |

| Iron | ≤ 0.01 % |

| Loss on ignition | 1.2 – 2.5 % |

| Granularity | ≤3.5 um |

| 325 mesh sieve through rate | 100 % |

| Sulphates | ≤0.2 % |

| Chlorides | ≤0.06 % |

| Bulk density | ≤0.25 g/cm3 |

| Whiteness | ≥95 % |

4. Packaging

The high purity magnesium oxide is generally packaged in the following ways:

20Kg or 10Kg / polywoven bag or kraft paper bag

5. Usage

a) premium lubricant grade magnesium oxide

Application: mainly used in the processing of advanced lubricants as cleaners, vanadium inhibitor, desulfurizer, greatly improving the density and rheology of lubricating film, reducing ash content. It facilitates the removal of mercury and lead to reduce the environmental pollution caused by lubricating oil or fuel waste. After surface treatment, the magnesium oxide can be used as a complexing agent, chelating agent, and carrier in the oil refining process, conducive to product fractionation and quality improvement. Especially when burning heavy fuel oil, adding MgO may protect the combustion chamber from the damage caused by the vanadic acid in the oil.

b) food-grade magnesium oxide

The magnesium oxide is used as food additive, color stabilizer, and pH adjusting agent: magnesium supplement for health care products and foods; bleaching agent for sugar refinement; pH regulating agent for ice cream powder; anti-caking agent and antacid for wheat flour, milk powder, chocolate, cocoa powder, grape powder, powdered sugar, etc. It may also be used in the production of toothpaste polishing agent and magnesium stearate.

c) medical grade magnesium oxide

Application: used in biopharmaceutical field as antacid, adsorbent, desulfurizer, deleading agent, complexing aid, pH adjusting agent, and isothiazolin quinolinone catalyst; in medicine field, used as laxative and antacid medicine, or used for suppression and mitigation of hyperacidity, as well as treatment of gastric ulcer and duodenal ulcer diseases. Its function in neutralizing stomach acid is stronger, slow and long-lasting, and does not produce carbon dioxide.

d) fluorescence grade magnesium oxide

Application: mainly used as the raw material for the production of trichromatic phosphor and other types of light body.

e) silicon steel grade magnesium oxide

Application: silicon steel grade magnesium oxide has good permeability (i.e., has a large positive magnetic susceptibility) and excellent insulating properties (i.e. conductivity can be as low 10-14us/cm dense state). It allows the silicon surface to form a good insulating layer and permeable media to suppress and overcome eddy current and skin effect loss of the silicon steel core in the transformer (referred to as iron loss), improving the insulation performance of the silicon steel sheet. It can also be used as a release agent for high-temperature annealing.

f) feedstuff grade magnesium oxide

Cow and sheep: a daily addition of magnesium oxide in 50-90 grams or by 0.5 percent of the fine fodder will be a good diet supplement to prevent the occurrence of magnesium deficiency. It also serves as an excellent rumen buffer agent, which regulates rumen fermentation, and can increase the absorption of breast milk synthetic precursors to improve milk yield and content of milk fat. The dosage of magnesium oxide in ruminant diets should be 0.5% -1.0%.

Poultry: the magnesium concentration in feedstuffs for common poultry is generally between 0.15% -0.22%, which varies according to age, variety and species.

Pig: the magnesium concentration in feedstuffs for pigs is generally between 0.13% -0.27%, which varies according to growth stage, weight and production purposes.

Freshwater fish: due to insufficient amount of magnesium dissolved in water, we need the appropriate magnesium supplementation in the feedstuff.

g) other purposes

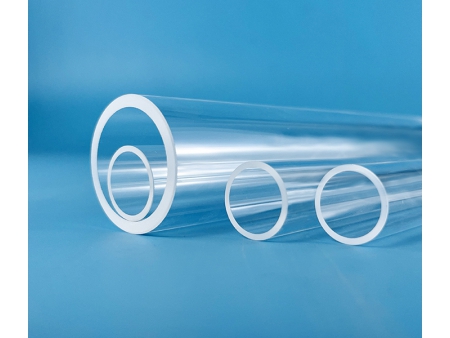

Applications: the high-purity magnesium oxide shows excellent alkali resistance and electrical insulation capability at high temperatures. It also has high thermal expansion coefficient, high thermal conductivity, and good optical transparency. The MgO is widely used as a high-temperature resistant material. In the field of ceramics, it is the raw material for translucent ceramic crucible and substrates. When used on ceramic substrates, it triples the aluminum oxide in terms of thermal conductivity, and the loss of electrolyte is only 1/10 of the latter. In the electrical field, it is the magnetic device filler, insulating material filler, and carrier. The high purity magnesium oxide is also the raw material for making high-purity fused magnesia, or used as analytical MgO.

6. Storage and Handling

The high purity magnesium oxide should be stored in dry and ventilated warehouse. Prevent moisture and heat, and handle the MgO with care so as not to damage the packaging.

Our magnesium oxide (MgO) is available in high purity and high activity grades. The advantages of our products include: high purity, high whiteness, uniform particle size, and controllable bulk density and specific surface area. From materials synthesis, pressure filtration, evaporation to drying and packaging, we pay attention to every aspect of every step to ensure product quality. Our high grade magnesium oxide is a gap-filling product in the domestic industry.

QIANGYUAN is one of the most outstanding chemical manufacturers in China. Our products are targeted at many different fields, and welcome to work with us.