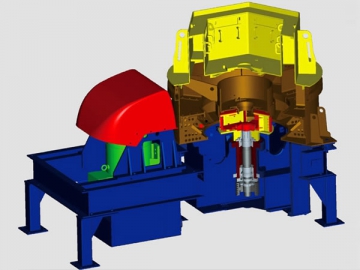

Jaw Crusher (New Type)

The Ormaise® CJ series jaw crusher is designed to be a perfect fit for stationary and for mobile rock crushing operations. The development of this jaw crusher was performed to greatly enhance this type of stone crushing machine's reliability, productivity, and safety. With maximum productivity up to 1225t/h, the crushing equipment is able to meet your large capacity material crushing demands.

This type of rock crusher is designed to use compressive force to break apart material for further processing or disposal. It is ideal for crushing ore, rocks, slags, etc, whose compressive strength is less than 320MPa.

Benefits of the CJ Series Jaw Crusher

1. The crusher machine's modular design and structure reduces weight and enhances impact resistance.

2. The adoption of high quality bearings increases the service life and improves performance.

3. Eccentric shafts employ heavy-duty forged steel alloy. The front and rear racks are made with high strength cast steel.

4. An optimized crushing structure achieves the best performance with the angle and stroke designed to maximize the crushing ratio.

5. Higher rotational speed increases throughput and material crushing times, which provides the jaw crusher with enhanced production efficiency.

6. Rapid adjustment of the discharge opening can be made through adjustment of the wedge at both sides.

7. Easy maintenance and installation, low operation cost.

Technical specifications of the Jaw Crusher

| Model | Feeding opening size (mm) | Power (kw) | Discharge size (mm) | Weight (kg) | ||||||||||||

| Capacity TPH | ||||||||||||||||

| 40 | 50 | 60 | 70 | 80 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 300 | ||||

| | 800×510 | 75-90 | 65-75 | 80-95 | 95-125 | 115-150 | 130-170 | 165-215 | 210-275 | 250-325 | 290-380 | 10800 | ||||

| | 1000×750 | 90-110 | 150 | 170 | 215 | 265 | 315 | 370 | 420 | 21000 | ||||||

| | 1100×850 | 132-160 | 190 | 210 | 255 | 310 | 370 | 425 | 480 | 402 | 25200 | |||||

| | 1250×950 | 160-200 | 290 | 350 | 410 | 470 | 530 | 590 | 650 | 37100 | ||||||

| | 1400×1070 | 200-220 | 385 | 455 | 520 | 590 | 655 | 725 | 48300 | |||||||

| | 1600×1200 | 200-250 | 520 | 595 | 675 | 750 | 825 | 72500 | ||||||||

| | 2000×1500 | 400 | 760 | 855 | 945 | 1040 | 1225 | 120000 | ||||||||

Notes

The above data for our jaw crushers is based on brittle material with moderate granularity and a density of 1.6t/m3. The processing ability in the table is the instantaneous maximum treatment capacity, and it changes according to material property, feeding graduation, feeding mode, moisture content, silt content, as well as the material's other physical properties. The discharge opening is defined as the distance from the tooth tip bottom to another jaw tooth tip top.