Simple Concrete Block Production Line

NOAH's simplified concrete block production line is one of the most cost-effective block making tools, and is widely used across practically every industry that requires the production of concrete blocks. You won't lose your shirt to have one such block production line, but you will see it pay for itself in a very short time. For small and medium-sized concrete block suppliers, these equipment sets would be an ideal option.

Features of Simple Concrete Block Production Line

1. Steel used to construct this concrete block production line is 6mm to 12mm in thickness. Components on the block machine are of well-known brands, such as Schneider electrical system and YUKEN solenoid valve. Properly designed electrical and hydraulic circuits ensure long time of use.

2. Advanced welding technology uses carbon dioxide as a shield gas to ensure every point of weld is solid, vibration-resistant, and able to withstand 8 years of use.

3. Advanced German MASA feeder system controls material flow rate and works best with material that contains large aggregates or sands. A consistent discharging feed allows material to be uniformly distributed over different molds. The resultant concrete blocks have uniform height.

4. Other desirable features include the Danish KVM direction guide system, synchronized gear box, and guide post. Copper bushes on the guide post are wear resistant.

5. Optimized concrete block production line greatly shortens the molding time, improves feeding speed, and ensures consistent material flow rate. Generally speaking the molding cycle would take about 15 to 20 seconds.

6. The secondary storage device prevents caking of concrete.

7. Hydraulic vibrating system delivers a vibration frequency up to 80Hz. The concrete mix liquidizes in as short as 2 to 3 seconds. The resultant concrete block has greater strength.

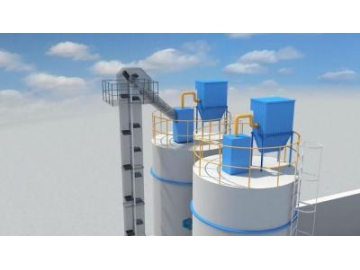

| 1 | Cement silo | 8 | Conveyor belt |

| 2 | Screw conveyor | 9 | Pallet feeder |

| 3 | Cement weighing system | 10 | Block conveyor |

| 4 | Batching machine | 11 | PLC control unit |

| 5 | Concrete mixer | 12 | Moulds |

| 6 | Block making machine | 13 | Block stacker |

| 7 | Hydraulic unit | 14 | Forklift |