Fully Automatic Concrete Block Production Line

Whatever the capacity you are looking for on a concrete block production line, please do rest easy that NOAH has the right solution for you. Depending on your budget, factory dimension, and the size of your production run, NOAH technical experts would be more than happy to assist you in model selection.

NOAH's fully automatic concrete block production line is designed and built on advanced German technologies. An extremely low defect rate, high productivity, reliability and level of automation allow our block production line to pop out as a natural choice when it comes to manufacturing concrete slabs, paver bricks, or more.

Here at NOAH customers are free to choose between QT9-15 and QT18-20 concrete block making machines based on your specific production needs. Typically operated by only 5 to 6 persons, the concrete block production line helps save on labor costs. Operators can keep these block machines operating continuously and safely 24 hours a day thanks to the effective process control. On the production line, concrete blocks are fast made with high density. In the autoclave, wet blocks are cured rapidly when surrounded by high-pressure steam. If you are an autoclaved block supplier and are looking for high-efficiency production line, then you might want to go with this concrete brick production line.

Applications of Fully Automated Concrete Block Production Line

Perforated bricks, solid blocks, paver bricks, and curb stones in building material industry, road paving and gardening industries.

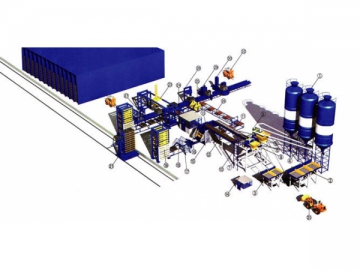

There are basically 5 parts that have made up this automated production system.

1. Weigh batcher

2. Molding system

3. Operation system

4. Curing system

5. Control system

Note that the entire production line is comprised of more than 30 equipment sets, including the cement silo, weigh batcher, conveyor, mixer, rotating brush, stacker, and molding system. Please refer to the table below for specific configurations.

| 1 | Cement Silo | 17 | Catwalk |

| 2 | Concrete Weigh Batcher | 18 | Block Brush |

| 3 | Pigment Weigh Batcher | 19 | Elevator |

| 4 | Screw Conveyor | 20 | Lower elevator |

| 5 | Cement Weigher | 21 | Programmer-controlled cart |

| 6 | Concrete Mixer | 22 | Cured Block conveyor |

| 7 | Pigment Mixer | 23 | Cuber |

| 8 | Concrete Mix Conveying Hopper | 24 | Pallet brush |

| 9 | Pigment Mix Conveying Hopper | 25 | Pallet Turnover |

| 10 | Mixing platform | 26 | Horizontal pallets conveyor |

| 11 | Belt conveyor for concrete mix | 27 | Tray Bin |

| 12 | Belt conveyor for pigment mix | 28 | Horizontal Packing Machine |

| 13 | Block making machine | 29 | Sword type Packing Machine |

| 14 | Computer control system | 30 | Film Wrapping Machine |

| 15 | Automatic Pigment Feeding system | 31 | Loader |

| 16 | Wet Block Conveyor | 32 | Forklift |