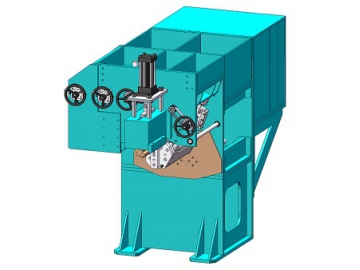

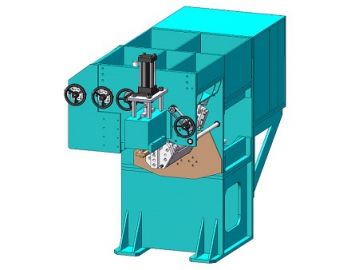

Tubeless Rim Band Coiler

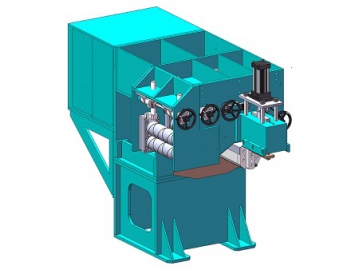

Tubeless rim band coiler, also called roll formers, are specially developed for the roll forming of steel wheel rims. This 3-roll forming machine features a durable structure, easy adjustment, high production efficiency and easy operation. It is also used to roll out two straight edges for subsequent butt-welding processes, achieving dual functions of both stamping and rolling. Stamping functions provided the needed marks on the rim band, including specifications, model, manufacturer, production date and more. Coiling is used for subsequent butt welding.

- This roll former, also known as wheel rim forming machine, is used to automatically coil the cut-into-length rim bands.

- A manual loading device is used.

- This roll former features a deburring function, allowing it to remove burrs at both ends of the rim bands. This prevents the die and operator in the next process from being scratched.

- This tubeless rim roller also supports stamping parameters, models, manufacturers, production date and other information on the rim bands.

- A levelling function is also available. Based on customer requirements, levelling the to-be-welded edge after coiling assists in reducing the need to use a separate flattener and facilitates following butt-welding processes.

- This rim roller features a horizontal structure, chain sprocket drive and handwheel adjustment, ensuring and facilitating reliable operation and easy maintenance.

- Depending on different customer requirements, the stamping heads are quick and easy to change.

- An automatic unloading platform can be added for a convenient, automatic conveyance of the work piece.

- This tubeless rim roller integrates deburring, stamping, coiling and flattening, saving labor costs and floor space.

- The spindle features a high-performance Japan NSK bearing to ensure a long service life.

- The electrical control system uses a German Schneider brand, featuring an excellent safety and reliability.

- On the small wheel rim production line, the rim roller will directly flatten the welding edge. After roll forming is complete, the work piece is transferred directly to the butt-welding process.

| No. | Model | Small rim line | Large rim line | Ultra large rim line | |

| 1 | Rim diameter range | 13~18inch | 17.5~26inch | 20~54inch | |

| 2 | Rim band thickness | ≤4mm | ≤8mm | ≤8mm | |

| 3 | Rim band width | 3~10inch | 5.5~16inch | 7~28inch | |

| 4 | Main machine specifications | Feeder | (Available) | (Available) | Available) |

| 5 | Deburrer | Optional | Optional | Optional | |

| 6 | Stamper | Optional | Optional | Optional | |

| 7 | Coiler | JYJ-600 | JYJ-800 | JYJ-1000 | |

| 8 | Power | 7.5kW | 11kW | 11kW | |

| 9 | Coiling roller diameter | 155mm | 165mm | 175mm | |

| 10 | Coiling roller speed | 88r/min | 63r/min | 63r/min | |

| 11 | Power supply | AC 380V/3phase/50Hz, Can be customized | |||

All information about this equipment is subject to change without warning and is for reference only. Customization services are available, with the final machine supplied based on agreed upon technical information.